Molybdenum Oxide Nanoparticle Aggregates Grown by Chemical Vapor Transport

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 April 2022 18:59

A study conducted by researchers at Daegu Catholic University in South Korea introduces advanced methods that combine chemical vapor transport (CVT) with quenching effects to create molybdenum oxide nanoparticle aggregates arrays consisting of fine nanoparticles (NPs) in a layered structure, grown vertically on individual carbon fibers of a carbon fiber paper (CFP) substrate.

The study titled “Molybdenum Oxide Nanoparticle Aggregates Grown by Chemical Vapor Transport” has been published in the journal Materials 2022, 15. The study was carried out by Yun-Hyuk Choi at the Daegu Catholic University, Korea.

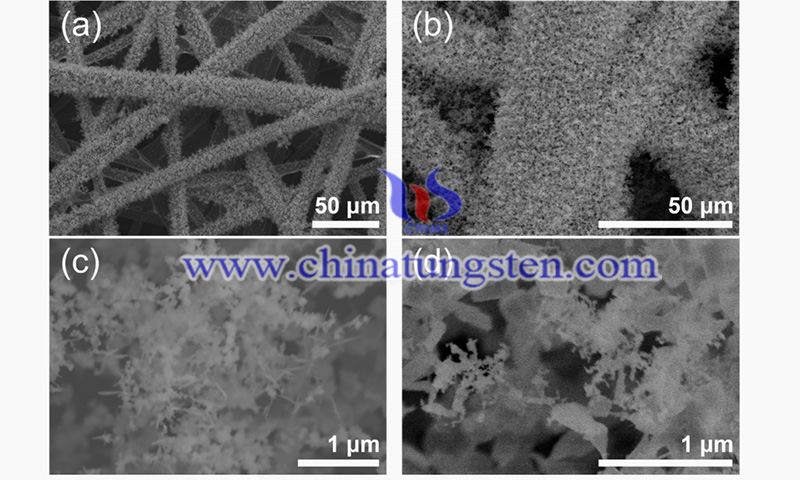

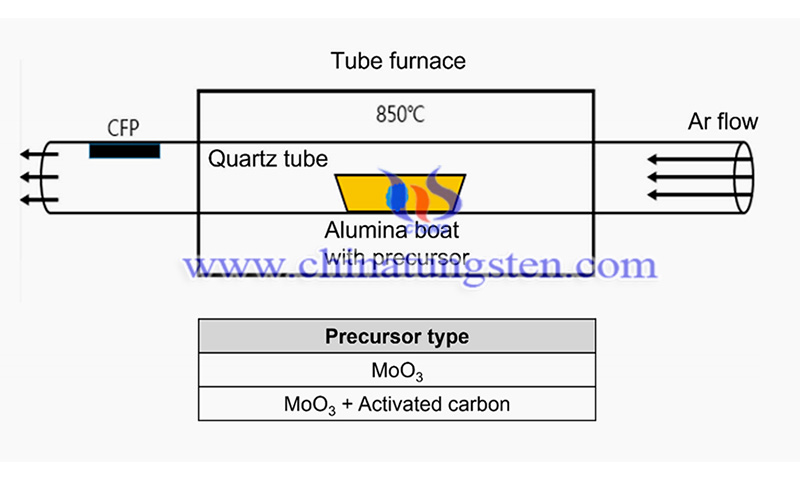

The obtained molybdenum oxide NPs maintain the stable α-MoO3 phase along with the metastable high-temperature γ-Mo4O11 phase through the quenching effect. In addition, this quenching effect forms thinner and smaller nanoparticle aggregates by inhibiting the growth and coalescence of primary particles. Molybdenum oxide nanoparticle aggregates were prepared using two different types of precursors: MoO3 and a 1:1 (mol/mol) mixture of MoO3 and activated carbon.

The results characterized using X-ray diffraction, Raman spectroscopy, X-ray photoelectron spectroscopy, and Fourier transform infrared spectroscopy showed that the relative amounts of α-MoO3 and γ-Mo4O11 within the prepared NPs depended on the precursor type; the amounts of α-MoO3 and γ-Mo4O11 were less in the NPs prepared using a mixture of MoO3 and carbon precursors.

This processing-structure study can serve as a basis for the development of high-performance nanomaterials for a variety of electronic and catalytic applications. Nanoscale materials have attracted a lot of attention for electronic, catalytic, sensor, and energy storage applications due to their high surface area and chemical activity that is different from that of bulk materials. Among the various synthesis methods for these materials, chemical vapor deposition (CVD) techniques in chemical vapor transfer have been widely used for the large-scale synthesis of uniform-sized nanomaterials.

However, in most cases, the obtained nanomaterials tend to have the poor size and shape homogeneity with sparse substrate coverage, which is caused by several simultaneous reactions. Especially in the growth of two-dimensional (2D) nanosheets, the predominant growth of the substrate surface with low chemical and catalytic activity is considered a major drawback for the application of conventional CVD techniques.

Therefore, in this work, the researchers shortened the cooling time during the CVD process in order to obtain thinner and smaller nanoparticle aggregates (secondary particles) by inhibiting the growth and coalescence of primary particles. This quenching effect of nanoparticle deposition from high temperature to room temperature was achieved by positioning the substrates outside the tube furnace.

In their microstructure, there is a metastable high-temperature phase and a stable phase. Their morphology exhibits a layered structure consisting of fine primary NPs. Furthermore, considering various electronic and catalytic applications such as gas sensors, supercapacitors, photocatalysts, environmental catalysts, and electrocatalysts, molybdenum oxide nanoparticle aggregates were deposited on conductive carbon fiber papers (CFPs) with high surface area.

The molybdenum oxide chosen as the case material in this work is a transition metal oxide with a versatile oxidation state and crystal structure that has been used in a wide variety of applications in electronics, catalysis, sensors, electrochromic, and energy storage systems.

The nonstoichiometric MoOx shows a more diverse suboxide structure with an average valence between Mo6+ and Mo4+. Among them, the metastable Magnéli phase Mo4O11 is one of the most frequently observed structures and appears as a low-temperature monoclinic η-phase or a high-temperature orthorhombic γ-phase (or called α-phase), and the reduction process of MoO3 includes the formation of Mo4O11 as an intermediate product.

The researchers investigated the structure and phases of molybdenum oxide NPs in terms of processing-structure relationships. Thin and small aggregates of molybdenum oxide nanoparticles were uniformly deposited on the CFP substrate by the chemical vapor transport method, combined with the quenching effect achieved by positioning the substrate outside the tube furnace. The obtained arrays of molybdenum oxide nanoparticles show a hierarchical structure of fine NPs that grow vertically and uniformly over the individual carbon fibers of the CFP substrate.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com