Tungsten Alloy Shielding for Plasma Accelerator

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2013 09:38

- Hits: 1941

Tungsten alloy shielding is necessary for plasma accelerator. Primary radiation is accelerated electron. Generally, electron beam which thickness is 1~2mm and shoots to target is focused and energy is also centralized. Primary radiation cannot damage to health when it locates at vacuum of accelerator. But as electron beam which is external application, it may damage to staffs for its high radiation strength.

Bremsstrahlung, caused by high energy electron beam bombarding to target interacts with X-ray, which energy is higher than 10MeV and accelerator parts. The process is called photon-neutron reaction and neutron caused during reaction is secondary radiation. Otherwise, some parts of accelerator may produce X-ray even most of its systems are not working.

Tungsten alloy shielding for plasma accelerator is used to protect staffs from radiation. Depending on heaviest density but small capacity, tungsten alloy material is more and more popular be used for making tungsten alloy shielding to protect body from plasma accelerator radiation. Compared with lead, tungsten alloy is much smaller but with heavier density, which is very helpful for high radiation absorption. It is more than 60% denser than lead, meanwhile, it has excellent machinability, good corrosion resistance. The most important thing is that, tungsten alloy is environment-friendly.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Where Tungsten is found

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2013 11:16

- Hits: 2037

Tungsten makes up a very small portion of the Earth’s crust and is a very scarce metal. Tungsten makes up just a miniscule 1.1 parts per million of the Earth’s crust. Just to get an idea, other elements such as Iron (about 63,000 parts per million) and lead (about 10 parts per million) make up a larger portion of the Earth’s crust. Tungsten’s closest “relatives” in the periodic table are usually considered to be molybdenum and tin, which make up similar parts per million of the Earth’s crust: 1.1. and 2.2 respectively.

Although, it sounds very small in the grand scheme of the parts per million of the Earth’s crust, the Earth’s crust is enormous and therefore there is still plenty of tungsten. However, it is never naturally found as a metal. Tungsten can only be found as a mineral, meaning it is found combined with other elements to form compounds. In fact, there are more than twenty tungsten minerals that can be found in nature, but only two of those are used to extract metal: scheelite and tungsten.

Tungsten is usually associated with a tin ore known as cassiterite that is usually found near granitic rocks. Tungsten is black-brown mineral and is one of the main sources for tungsten, as mentioned above. When found in its natural state, wolframite will contain varying levels of manganese tungstate and also iron tungstate. Depending on the composition of tungsten mineral, it will be called a different name. If the mineral contains more than 80% manganese tunsgstate is known as hubnerite, whereas if the mineral consists of more than 80% iron tungstate it will be known as ferberite.

Whereas tungsten will be found in that black brown color, Scheelite varies in color from white to green. Also, under ultraviolet light, pure scheelite will glow. Unlike wolframite that will have manganese tungstate or iron tungstate, scheelite will consist of calcium tungstate. Whether it is found as tungsten or scheelite, the tungsten metal can eventually be turned into a variety of things, including the tungsten carbide rings that are becoming increasingly popular.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Cube for Clock

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2013 10:56

- Hits: 1916

When clock vibrates, there is an eccentric motion, which is caused by eccentric motor with vibrating components occurs. As the center of the gravity is eccentric, and is not in the rotor of motor, then the clock vibrates. In this case, machinery component with good properties of wear resistant and high specific gravity is required. Tungsten alloy cube is the best material to make tungsten alloy vibrator used in clock.

Tungsten alloy cube is excellent material for making tungsten alloy vibrator. Since the density of tungsten alloy cube is so high and the maximum density should be 18.6g/cm3. Tungsten alloy cube is popular where small component with relatively large mass is needed, for example: the tungsten alloy vibrator used in clock.

Tungsten alloy vibrators in clock are one of our leading products. Compared with other materials, tungsten alloy has the advantages of accurate weight, and non-magnetism. In particular, since a motorized weight usually produces the tungsten alloy vibrators, lighter-weight phones may have weaker vibrating mechanisms.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Paperweight

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2013 10:27

- Hits: 2245

Paperweights are decorative objects, designed to hold sheets of paper on a surface to prevent wind from blowing them away. Tungsten paperweights have a long history in China. It can be traced back to the birth of paper.

In ancient China, tungsten paperweights were necessary equipment in sanctum. For one of the reason was Chinese paint art and handwriting always use brush and larger paper. Popular size of paper may 300mm x 500mm, and the large size paper may be larger than 2000mm x 1000mm. Tungsten paperweights are now important addition to "wen fang si bao" (the four treasures of the study, i.e. writing brush, ink stick, ink slab, paper), were very important for everyone who can read and write.

In the West, first documented appearance of paperweight can be traced to the Exhibition of Austrian Industry held in Vienna in 1845. Tungsten paperweights of Pietro Bigaglia of Venice were displayed at this exhibition. Knowledge of their existence was reportedly soon brought to the attention of the Saint-Louis glass factory in France.

Tungsten paperweights are composed of metal alloy, tungsten heavy alloy. The alloy allows for maximum hardness and rigidity without sacrificing tensile strength. Tungsten paperweights are polished with diamond tools, and it takes a brilliant high polish and resists scratching longer than any metal ever offered to the public. Roughly ten times harder than 18k gold and four times harder than titanium, tungsten paperweights will never bend or lose their shape. Paperweight made of tungsten can be last for a long time.

It is also possible to have "custom" tungsten paperweights made to your specifications. Tungsten Paperweights never worn, never rust, high-density, high-performance paperweight!

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

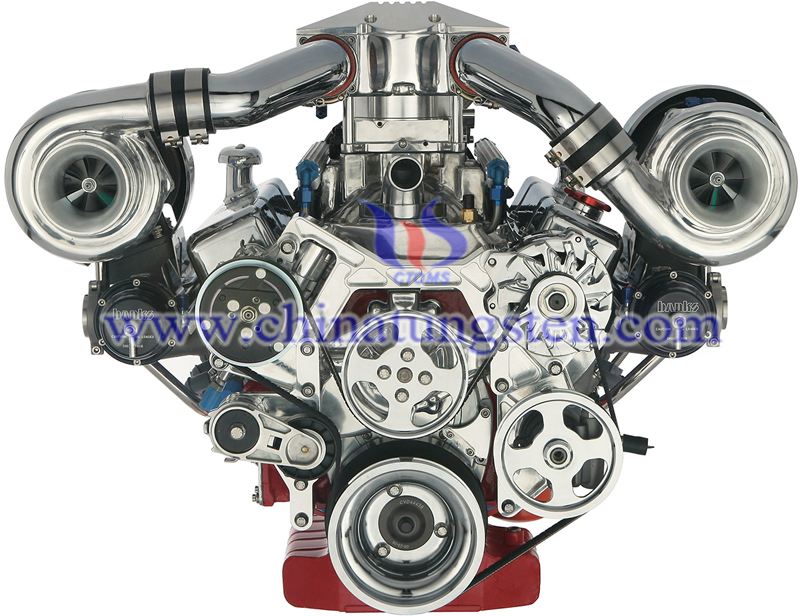

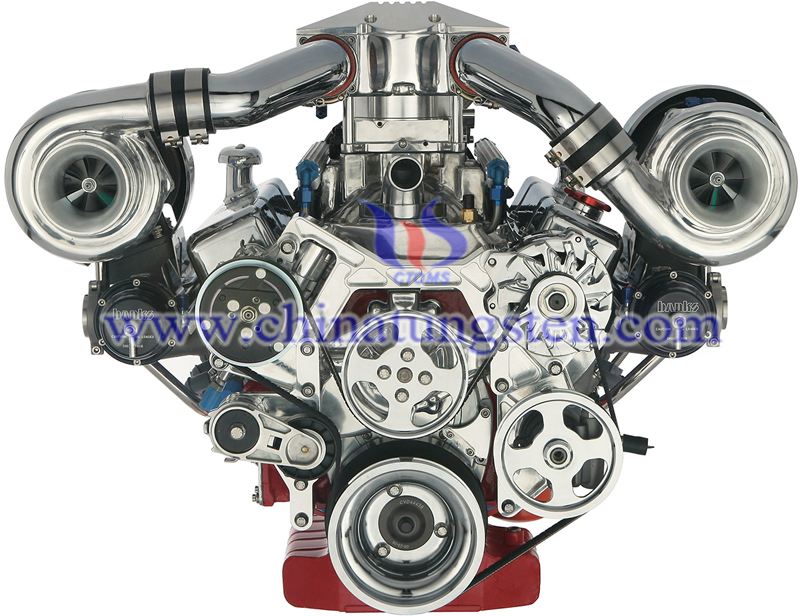

Tungsten Heavy Alloy Turbo Engine

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2013 10:15

- Hits: 2179

Tungsten heavy alloy turbo engine is the heat engine which is conditioned by its maximum intake temperature, and turbo engines are limited by the behavior of the constituent materials of the articles that are most exposed to heat and constraints.

Concerns for environmental protection have led designers of aviation tungsten heavy alloy turbo engine to search for means to reduce the proportion of pollutants in the exhaust gases of the engines. It is known that the principal problems in the matter of pollution of aviation tungsten alloy turbo engines are, on the one hand, the emission of carbon monoxide, of hydrocarbons, and of various unburnt residues during operation on the ground and, on the other hand, the emission of nitrogen oxides and of particles during take-off and during cruising at altitude. Therefore, tungsten alloy turbo engines are increasingly accepted by public.

Tungsten heavy alloy turbo engine is generally of optimized rating for take-off or near take-off operation. This signifies that, in the primary zone of the combustion chamber, a fraction of the air flow of the compressor is introduced so that, with the injected fuel, the fuel-air mixture in this zone would be essentially stoichiometric in turbo engines. Under these conditions, due to the levels of temperature and high pressures, as complete as possible a combustion is obtained, combustion yields greater than 0.99 are attained, the speeds of the chemical reaction being optimum for these stoichimoetric mixtures.

The first two times can be considered negligible at high ratings because of the pressures which are attained, but it is not so at low ratings. In fact, in order to increase the speed of the vaporization of the fuel, it must be transformed into fine droplets, which, in normal operation, is easily realized by the conventional mechanical atomizing injector, but the performance which is obtained in the lower ratings is poor. This is due to the fact that, if the fuel is well divided into droplets, these are poorly mixed with air in the primary zone and local zones would appear which have a richness which is too high. In the end, it would be necessary that each droplet would have around it the quantity of gas necessary for its vaporization and for its combustion, i.e., a quantity of gas which results in a stoichiometric mixture with the oxygen molecules after complete vaporization. In order to accomplish this, systems such as aerodynamic injection have been proposed. Aerodynamic type injectors generally comprise whirling, or swirled vanes through which the air from the compressor is introduced, which serves to atomize the fuel. An air/fuel pre-mixture is thus obtained. All of these solutions, which allow an improvement in the combustion yield have, however, a maximum efficiency only for values sufficient for the pressures and temperatures of the air at the chamber inlet. All of these factors are advantageous for a reduction of the reaction times and could lead to a reduction of the length of the combustion chamber for tungsten heavy alloy turbo engine and thus to a limitation of the dwell time of the gases in the latter. In the whole working environment, material of heat-resistance is required, therefore, tungsten heavy alloy for turbo engine is widely used for that.

A first objective of tungsten heavy alloy turbo engine is to provide a novel solution to the problem of low operating combustion for a chamber which includes aerodynamic type or pre-atomization injectors, which are mounted in the base of the chamber. In fact, in the case of a conventional chamber of tungsten heavy alloy turbo engine, which is arranged to provide a stoichiometric mixture at take-off, about one-third of the air flow necessary for the combustion of tungsten alloy turbo engine is introduced in the injection system and two-thirds by the primary orifices.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

How Tungsten is Isolated and Refined

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2013 09:35

- Hits: 2023

Once the tungsten ore that was extracted from the earth is ready for processing and has been prepared. The process in preparing the tungsten is the same as has been used since it was initially extracted by the Spanish brothers and chemists Juan Jose and Fausto d’Elhuyar y de Suvisa. However, unlike the method used by the d’Elhuvar y de Suvisa brothers, modern extraction and preparation requires an extra, complicated step. Today, a complex chemical extraction is produced during the process. The chemical is called ammonium paratungstate, or more commonly known as APT.

APT is produced in two different ways. The methods are acid leaching and autoclave-soda. Ore is mixed with sodium carbonate under high temperatures and pressure in the autoclave-soda process. APT crystals are formed after ammonia is added to sodium tungstate solution.

In the acid leaching process, tungsten ore is broken down using hydrochloric acid making solid tungstic acid and calcium chloride. Ammonia is used as in the autoclave-soda process. Ammonia is used to dissolve tungstic acid. After evaporating and filtering the mixture, crystals of APT are produced.

Now, you may be wondering what crystals have to do with the tungsten carbide rings you purchased at your local or online retailer. Well, the process is still yet to be completed. The next part of the process is to make tungsten oxide.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy for X-ray

- Details

- Category: Tungsten Information

- Published on Friday, 12 July 2013 08:44

- Hits: 2109

Tungsten alloy is used for shielding against X-ray in medical. With the development of radiation shielding for X-ray equipment, especially constantly carrying out radiation shielding and safety regulation or standard, awareness of radiation shielding is strengthened in generally. Now accidents caused by X-ray are few. However, in the past, if did not notice intermittent exposure to control irradiation of X-ray, it may cause radiation injury to the skin of patient and medical staffs’ hands when utilizing fluoroscopic viewing to carry out fracture reduction and searching foreign matter inside body. At the beginning of 1980’s, one hospital in China used 10mA portable X-ray equipment which had low effectiveness of shielding to search the bullet in buttock of a child who shot by air pistol. Medical staffs were lack of knowledge about radiation shielding and time of fluoroscopic viewing was too long. That caused II~III degree acute radiation burning accident to part skin of child. The child accepted symptomatic treatment in hospital for several moths and also needed skin grafting after half a year. It also happened that medical staffs could not control fluoroscopic viewing time, resulting in over irradiation of X-ray to medical staffs’ hands and radiation injury when carrying out fracture reduction and searching foreign matter inside body.

Traditionally, lead was used as raw material for radiation shielding. However, lead had toxicity which may cause pollution. The density of tungsten alloy is higher than lead by 60%. High density of tungsten alloy allows a reduction in physical sizes of shielding components without compromising effectiveness of shielding characteristic. Otherwise, tungsten alloy has the advantage of non-toxicity. Tungsten alloy is suitable for radiation shielding.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Understanding the Characteristics of Tungsten

- Details

- Category: Tungsten Information

- Published on Thursday, 11 July 2013 15:45

- Hits: 2135

Tungsten is a very unique metal with very unique characteristics. Tungsten is a very heavy metal. In fact, tungsten derives its name from the Swedish words tung and sten, which means “heavy stone”. In terms of weight compared to lead, a cubic inch of lead weighs half as much as a cubic inch of tungsten. Just to put in as a perspective, a cubic inch of lead weighs about six and a half ounces (a little less than half a pound).

Much has been said about tungsten’s toughness and high durability, but it is also pretty brittle. In fact, it is possible to cut a piece of with a hacksaw. Some tungsten wedding bands have been known to break if dropped from a fairly high distance. Nonetheless, tungsten carbide is still one of the toughest and strongest of all metals known to man.

One of tungsten’s most amazing characteristics comes from its ability to withstand heat. With the exception of carbon, tungsten has the highest melting point of all elements. Tungsten has a melting point (the point where it changes from a solid to a liquid) of 6,152 degrees Fahrenheit (3,410 degrees Celsius). At 4,982 degrees Fahrenheit, another “tough” metal – Iron – is already boiling. At high temperatures, tungsten keeps its profound strength and does not begin to expand nearly as much as other metals. Because of its ability to remain strong under high temperatures, tungsten is used in space travel.

Another interesting characteristic of tungsten is that it does not react with many other substances including acids. Tungsten is resistant to most acids, which also aids in the jewelry industry. The lack of reaction with acids and other elements prevents your finger from turning green.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Collimator for Radiotherapy

- Details

- Category: Tungsten Information

- Published on Thursday, 11 July 2013 10:02

- Hits: 2048

Tungsten alloy collimator is widely used for radiotherapy. In China, radiotherapy was begun in 1930’s. Radium Hospital (Fudan University Shanghai Cancer Center), build in 1931 and Peking Union Medical College Hospital (having 200mg radium needle, a 200kV X-ray therapy apparatus and a 120kV X-ray therapy apparatus), build in 1932, were the first hospitals launching the earliest radiotherapy in China. At the end of 1950’s, China imported the first 60Co therapy apparatus, high energy ray device. China imported the first betatron in 1968 and the first liner accelerator in 1975. In recent years, radiotherapy has developed unprecedentedly. All of new radiotherapy techniques are developed including three-dimensional stereotactic radiotherapy (gamma knife, X-ray knife, conformal therapy and intensity modulated radiotherapy). Researches on tumor radio physics and radio biology also achieve fruitful results. In recent years, hospitals adding radiotherapy in every province, city, prefecture-level city, county-level city even small towns are more and more. Radiotherapy equipments are more and more advanced.

Tungsten alloy collimator is used for guiding X-ray to protect patients and doctors from radiation. Density of tungsten alloy is higher than lead by 60%. The high density allows a reduction in physical sizes of collimator without compromising effectiveness of shielding characteristics. Otherwise, tungsten alloy has the advantage of non-toxicity. So tungsten alloy is more suitable for collimator, compared with lead.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Counterweight Block

- Details

- Category: Tungsten Information

- Published on Thursday, 11 July 2013 09:48

- Hits: 1937

The high proportion of raw materials for production to clean the metal tungsten alloy counterweight block is pollution-free, in line with international environmental standards, proportion (> 18g/cm3), small size. Therefore, resistance to strong winds, light into the water, sinking fast, and sinker the best alternative to products sold in Europe and other developed countries.

Tungsten alloy counterweight block including: tungsten alloy golf weight, car weight of tungsten alloys, tungsten alloys and fishery pendant with heavy tungsten alloy ship weight, tungsten alloy aircraft weight and so on.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com