Coated Tungsten Carbide Insert Plastic Deformation Resistance (1)

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 June 2015 15:29

- Written by lucy

- Hits: 441

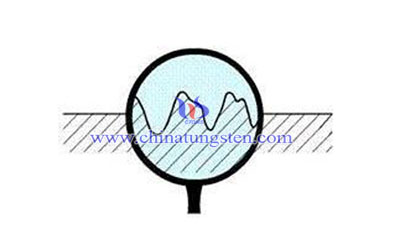

It is claimed that the cutting performance of coated tungsten carbide insert regarded to specific wear type could be improved by single actions but the side effect will be pronounced at the same time when examining other wear properties. As a result, in order to get an optimization tool performance, a decent design of coated tungsten carbide insert should take all these properties into account and make balance among them. One important balance in terms of milling alloyed steels with tungsten carbide insert is between cutting edge plastic deformation and edge chipping resistance.

Decreasing the binder content is one of the most common way to level up the resistance to plastic deformation and abrasive wear resistance. However this method will bring down the toughness of the cutting insert, as the vibrations and presence of casting or forging skin are affected by these factors, what’s more it will largely short the tool life.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com