Stability of Barium Tungsten Electrodes in High-Power Laser Systems

- Details

- Category: Tungsten Information

- Published on Friday, 06 June 2025 18:54

- Written by Zhenghua

- Hits: 6

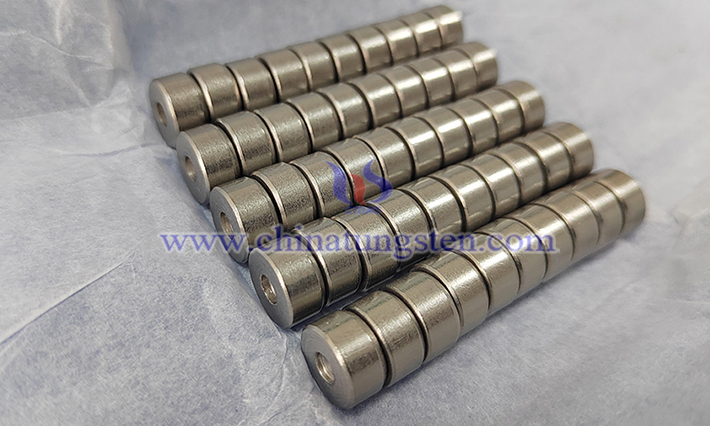

The stability of barium tungsten electrodes in high-power laser systems is a key factor in ensuring system performance consistency and service life. Barium tungsten electrodes are usually made of tungsten, which is widely used in laser systems due to its high melting point and good durability, while the addition of barium is usually used to enhance the electron emission performance of the electrode. In high-power laser applications, the electrodes need to withstand extreme conditions, including high temperatures, electrical stress, and possible material degradation, all of which affect their stability.

1. Main Factors Affecting Stability

1.1 Thermal Management

High-power laser systems generate a lot of heat, which causes thermal expansion and contraction of electrode materials. Tungsten has high thermal conductivity and low thermal expansion coefficient, making it less likely to deform or crack in this environment, making it very suitable for use as an electrode. The addition of barium can further improve thermal stability because it helps the electrode dissipate heat more effectively, thereby reducing damage caused by temperature fluctuations.

1.2 Electrical Stress

In high-power laser systems, electrodes are exposed to strong electric fields and currents, which can cause surface erosion or sputtering. Barium tungsten electrodes, due to their high work function design, are able to reduce unwanted electron emission, thereby reducing the risk of surface damage. This property allows them to maintain stability during long-term operation.

1.3 Material Degradation

Material degradation is a potential problem when electrodes are exposed to reactive gases or high-energy particles. Tungsten has good chemical inertness and can resist corrosion, while barium can act as a "sacrificial layer" to protect the underlying tungsten from degradation. This combination helps maintain the structural integrity and performance of the electrode.

2. Potential Disadvantages and Limitations

Although barium tungsten electrodes excel in stability, there are some potential disadvantages. For example, the addition of barium may make the electrode more susceptible to contamination, especially if the system is not sealed or operated properly. Contaminants may change the electron emission characteristics, resulting in unstable laser output. In addition, the manufacturing process of barium tungsten electrodes is more complicated and costly than pure tungsten electrodes, which may be a trade-off in some applications.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com