Analysis of High Temperature Resistance of Tungsten Crucible in Vacuum Furnace

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 16:03

- Hits: 8

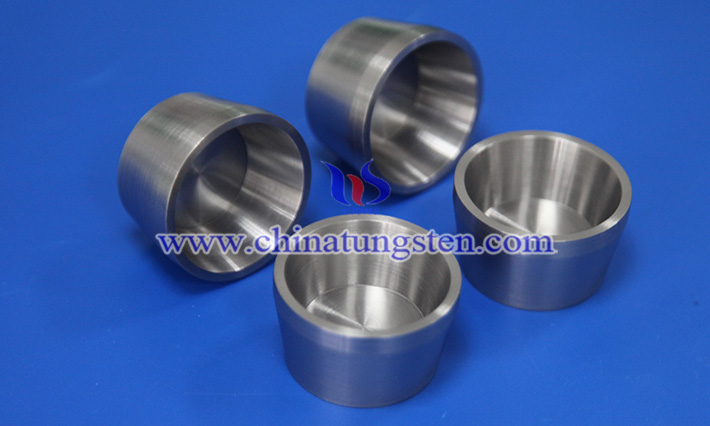

to have high heat resistance, evaporation resistance and structural stability. With its unique properties, tungsten crucible plays an irreplaceable role in high-temperature precision processes including aerospace, semiconductors, special alloys, rare earth metallurgy, etc.

In this paper, the high temperature resistance of the crucible in vacuum furnace will be systematically analyzed from the aspects of thermal stability, sublimation resistance, heat conduction behavior, and thermal stress response.

1. Extremely high melting point ensures structural stability

Tungsten is the element with the highest melting point of any known metal, with a melting point of up to 3410°C, which provides a solid guarantee for the high-temperature process of tungsten crucibles in vacuum furnaces. In some processes (such as tantalum, rhenium, titanium alloy smelting), the operating temperature of the vacuum furnace can reach 1800–2800 °C, and general metals such as nickel, molybdenum or tantalum will soften, deform or even melt in this temperature range, while the crucible made of tungsten can still maintain the structural integrity without plastic deformation or collapse, ensuring the safety and stability of the process.

2. Good anti-evaporation performance

Under the condition of high temperature vacuum, the vapor pressure of metal materials increases significantly, which is prone to sublimation and material loss. Tungsten has an extremely low vapor pressure, and its sublimation rate is much lower than that of other metal materials, even at high temperatures of 2500°C. This property significantly extends the service life of the crucible in a high-temperature vacuum furnace, especially for processes that require material stability, such as crystal growth and melting of high-purity materials. Studies have shown that the sublimation rate of tungsten is only 1/3 of that of molybdenum in a 10⁻⁵ Pa vacuum, which greatly reduces the risk of material loss and contamination.

3. High thermal conductivity and uniform temperature distribution

Tungsten has a high thermal conductivity (about 173 W/m·K at room temperature), which means that it can quickly conduct heat to the entire crucible structure after being heated, achieving temperature uniformity and avoiding local overheating and thermal stress concentration. In vacuum furnaces, this good thermal conductivity helps to achieve a uniform distribution of the thermal field, which is beneficial for controlling melt flow, crystal growth direction, and sintering compactness to improve process consistency.

4. The ability to resist thermal shock is strong, and the thermal fatigue life is long

Although tungsten has a low coefficient of thermal expansion (about 4.5×10⁻⁶/K), it has good retention of high-temperature strength and stable thermal conductivity, and shows good thermal shock resistance in periodic heat treatment. During vacuum furnace start-up, heating and cooling, the crucible can effectively resist the thermal stress caused by rapid temperature changes, thereby reducing failures such as cracking, spalling or warping. In addition, the grain growth rate of the crucible is slower at high temperatures, and it is not easy to form coarse grains and cause structural embrittlement, so that it has a long thermal fatigue life.

5. Excellent chemical inertness and compatibility

In a vacuum environment, tungsten is extremely chemically inert to most metals, oxides and gases, and does not react easily with melts, so it can effectively prevent inclusions, contamination or secondary reactions when smelting rare metals and semiconductor materials (such as germanium, silicon, gallium arsenide) and improve product purity. Even in the case of contact with highly reactive metals, such as the addition of alloying elements such as molybdenum and tantalum, it also exhibits good interfacial stability and wetting behavior, which further improves the adaptability in vacuum superalloy systems.

6. Limitations and optimization directions in application

Although tungsten crucible has excellent performance in vacuum furnaces, it is easily oxidized to WO₃ in the presence of oxygen, and it is brittle at high temperatures, and has limited resistance to mechanical shock. Therefore, in the practical use of crucibles, it is still necessary to pay attention to avoid oxidizing atmospheres, and improve their mechanical strength and service life by optimizing the preparation process (such as hot isostatic sintering and surface coating treatment). Future research in the fields of nanostructure optimization, coating technology, and composite materials is expected to further broaden the application boundaries of W crucibles under more extreme conditions.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com