Effect of Coating Preparation Method on Oxidation Behavior of W-Based Materials

- Details

- Category: Tungsten's News

- Published on Tuesday, 02 May 2023 17:17

- Hits: 524

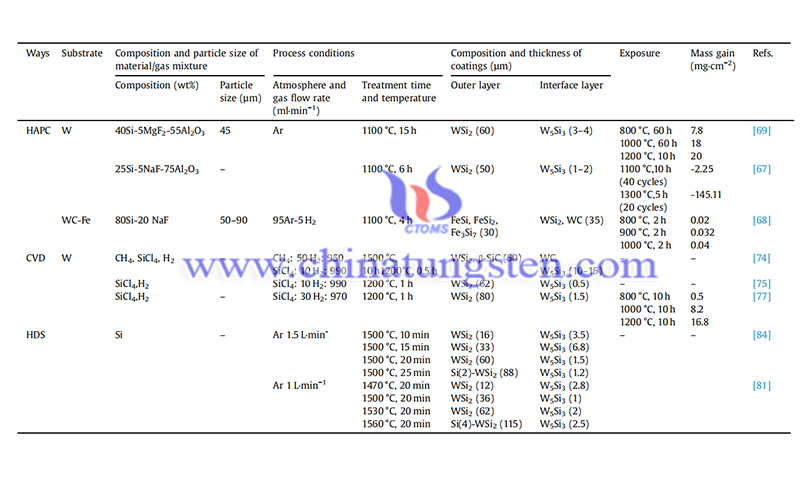

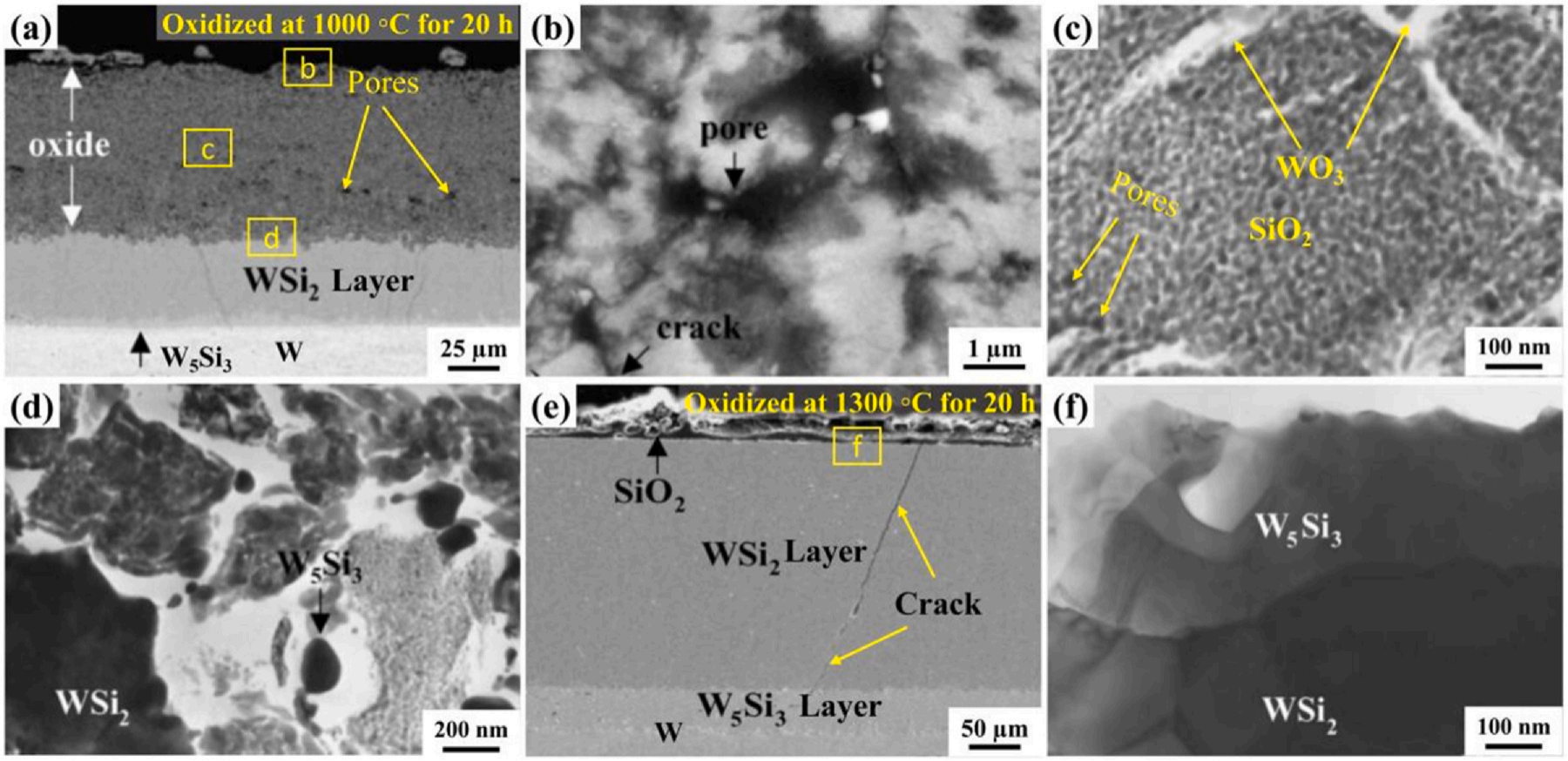

Researchers summarize the effects of different coating preparation methods on the coating composition and oxidation behavior of W-based materials. It can be seen that the silicide coating consists mainly of a thick WSi2 layer and a thin W5Si3 layer. The HAPC coating requires a longer time due to the relatively low diffusion temperature. After 4~15 hours of treatment at 1100 °C, the thickness of the coating is only 30~60 µm. However, using CVD technology, the thickness of the coating can reach 50~80 microns after 0.5~1 hour of deposition at 1200°C. In contrast, the HDS technique is very efficient for coating preparation. By depositing at 1500°C for 0.25~0.42 h, coatings with thicknesses of 36~88 µm can be obtained.

Si-WSi2 Coating Prepared by HDS

- Details

- Category: Tungsten's News

- Published on Monday, 01 May 2023 12:27

- Hits: 498

Zhang et al. prepared Si-WSi2 coatings on W substrates by hot-dip silicon-plating (HDS) technique. The HDS method involves placing a solid infiltration source into a corundum crucible under a high-temperature protective atmosphere, heating it until it is completely melted, and maintaining the temperature for a certain period of time. The processed sample is then slowly placed into the crucible and the coating is formed on the surface of the substrate by interpenetration between the substrate and the melt. This method is considered to be a cost-effective coating preparation method, which features short coating preparation time, high deposition temperature, uniform coating composition, smooth surface, and compact structure.

WSi2/β-SiC Nanocomposite Coating Prepared by CVD

- Details

- Category: Tungsten's News

- Published on Monday, 01 May 2023 12:20

- Hits: 498

The WSi2/β-SiC nanocomposite coating were obtained by a two-step chemical vapor deposition (CVD) process. EPMA results showed that the carbide coatings consisted of a WC layer and a W2C layer with corresponding thicknesses of 2 and 17 µm, respectively. The WSi2 layer with a thickness of about 50 µm was then obtained by silicification at 1200 °C for 30 min.

Antioxidant Coating for W-Based Alloys

- Details

- Category: Tungsten's News

- Published on Sunday, 30 April 2023 15:16

- Hits: 462

Surface antioxidant coating technology for W-based alloys is an important measure for the oxidation protection of material surfaces and has been widely used for the oxidation protection of refractory metals. Among them, halide-activated packet cementation (HAPC), chemical vapor deposition (CVD) technology, and hot dipping silicification (HDS) technology have won the favor of more researchers in the oxidation protection of W-based materials due to their excellent process conditions.

Oxidation Mechanisms of W-Based Alloys

- Details

- Category: Tungsten's News

- Published on Sunday, 30 April 2023 14:55

- Hits: 489

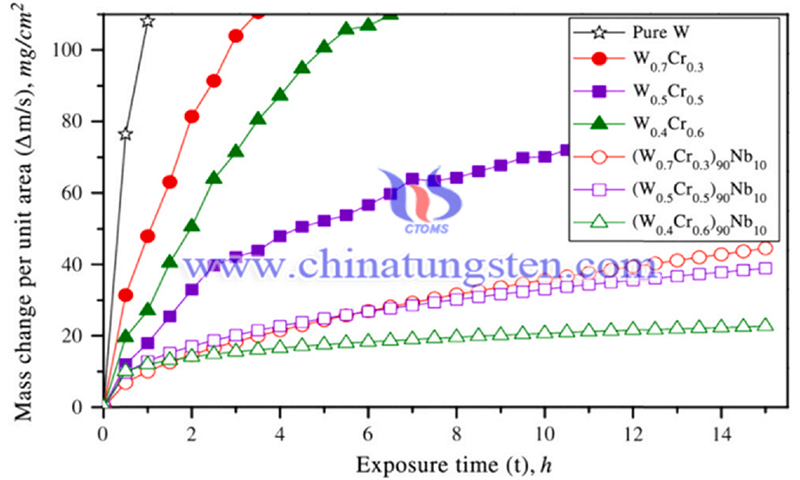

The oxidation mechanisms and failure mechanisms of W-based alloys indicate that the oxidation process can be divided into two distinct phases. The rate of oxide film formation and the stability of the structure are the key factors affecting the oxidation resistance of W-Cr alloys. the Si and Cr elements are easily oxidized to form a stable protective film. Therefore, the oxidation properties of W-Si-based alloys and W-Cr-based alloys have been extensively investigated.

Oxidation Behavior of W-Cr-Y-Zr Alloy

- Details

- Category: Tungsten's News

- Published on Sunday, 30 April 2023 14:39

- Hits: 564

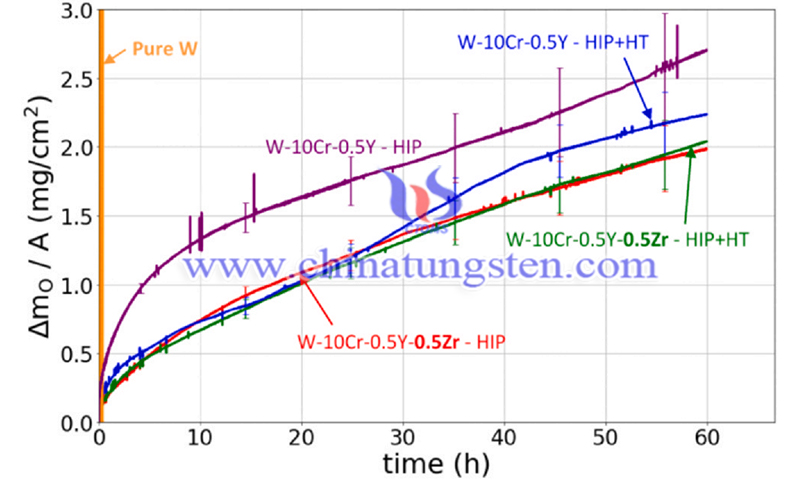

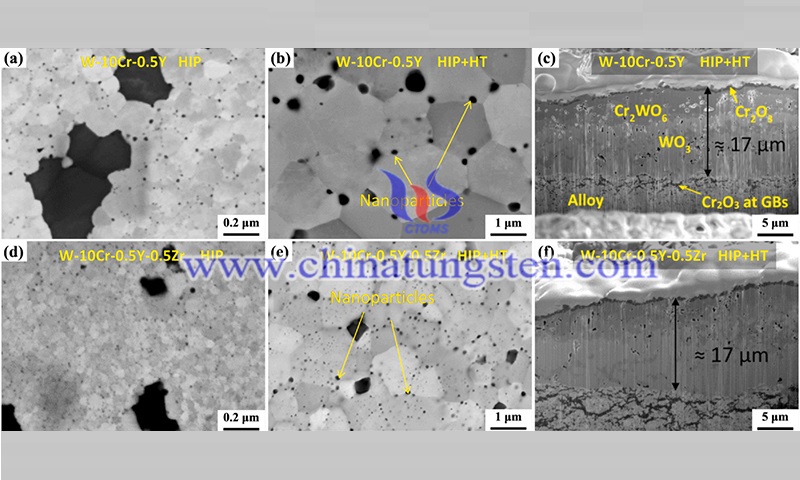

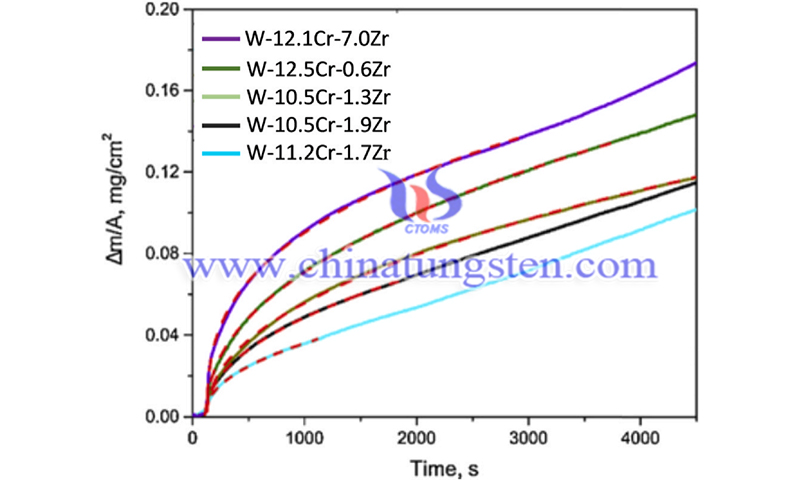

Researchers prepared W-Cr-Y-Zr alloy and investigated its oxidation behavior. Elisa et al. prepared W-10Cr-0.5Y and W-10Cr-0.5Y-0.5Zr (wt%) alloys by HIP and heat treatment (HT) techniques. The surface image results show the morphology of the heat-treated W-10Cr-0.5Y and W-10Cr-0.5Y-0.5Zr (wt%) alloys with heat treatment temperatures and times of 1550°C and 1.5 h.

China’s APT Price Breaks Through $312.9/mtu on April 27, 2023

- Details

- Category: Tungsten's News

- Published on Friday, 28 April 2023 15:56

- Hits: 719

Analysis of latest tungsten market from Chinatungsten Online

The tungsten carbide powder and ferro tungsten prices continue to rise and APT price breaks through $312.9/mtu on April 27, 2023 mainly due to the strong rised mentality of tungsten raw material suppliers as well as the external speculation.

China Tungsten Price Is in the Upward Trend at the End of April 2023

- Details

- Category: Tungsten's News

- Published on Thursday, 27 April 2023 17:54

- Hits: 663

Analysis of latest tungsten market from Chinatungsten Online

China tungsten price is in the upward trend at the end of April 2023 affected by the rised mentality of raw material suppliers, although the trading activity in the market remains low.

China’s Tungsten Powder Price Keeps Firm on Tight Supply

- Details

- Category: Tungsten's News

- Published on Wednesday, 26 April 2023 17:22

- Hits: 542

Analysis of latest tungsten market from Chinatungsten Online

China’s ammonium paratungstate (APT) and tungsten powder prices keep firm on April 25, 2023 mainly due to the tightening supply of raw materials as well as the strong rised mentality of suppliers.

China Rare Earth Market - April 26, 2023

- Details

- Category: Tungsten's News

- Published on Wednesday, 26 April 2023 17:19

- Hits: 453

China rare earth market is still not good on April 26, 2023, mainly reflected in the decline in the prices of praseodymium, neodymium, dysprosium, terbium and NdFeB to varying degrees, and the actual transaction volume is lower than expected. This is mainly due to the fact that the weak downstream demand is difficult to improve and the recent market spot volume has not decreased significantly.

sales@chinatungsten.com

sales@chinatungsten.com