Performance Comparison of Tungsten and Copper Targets

- Details

- Category: Tungsten Information

- Published on Thursday, 11 September 2025 20:22

- Written by Xiaoting

- Hits: 34

In the fields of semiconductor manufacturing and thin film deposition, the choice of target material significantly impacts process efficiency and product quality. Copper and tungsten targets, as two common sputtering targets, each have distinct advantages and disadvantages in terms of physical properties, chemical stability, and application scenarios.

Read more: Performance Comparison of Tungsten and Copper Targets

Performance Comparison of Tungsten and Molybdenum Targets

- Details

- Category: Tungsten Information

- Published on Thursday, 11 September 2025 20:19

- Written by Xiaoting

- Hits: 36

In the fields of thin film deposition and advanced manufacturing, the choice of target material significantly impacts process efficiency and product quality. Molybdenum and tungsten targets, as refractory metal targets, are widely used in the production of solar cells, display panels, and high-temperature coatings due to their high melting points and chemical stability.

Read more: Performance Comparison of Tungsten and Molybdenum Targets

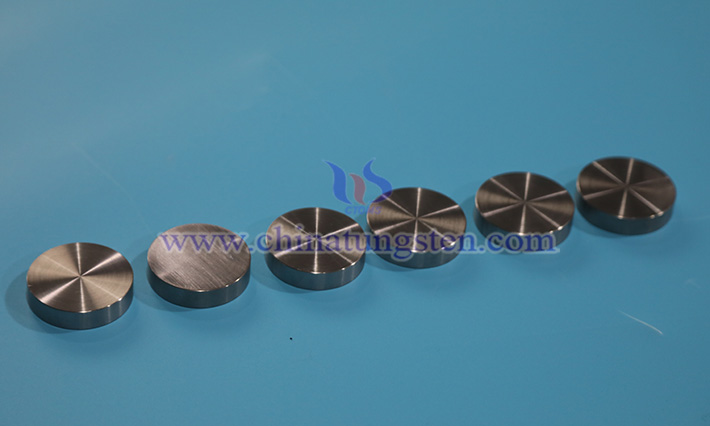

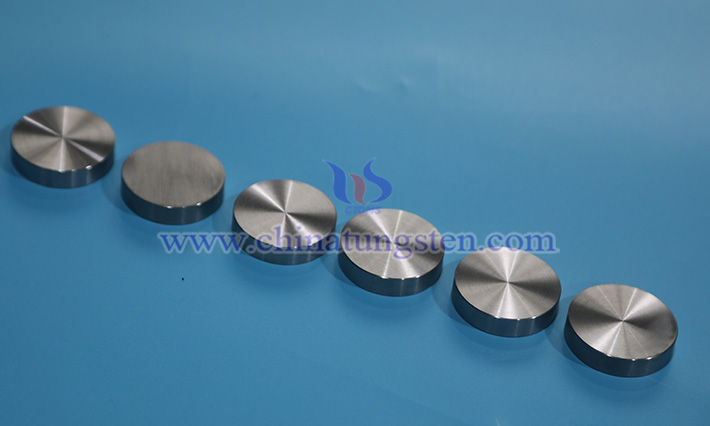

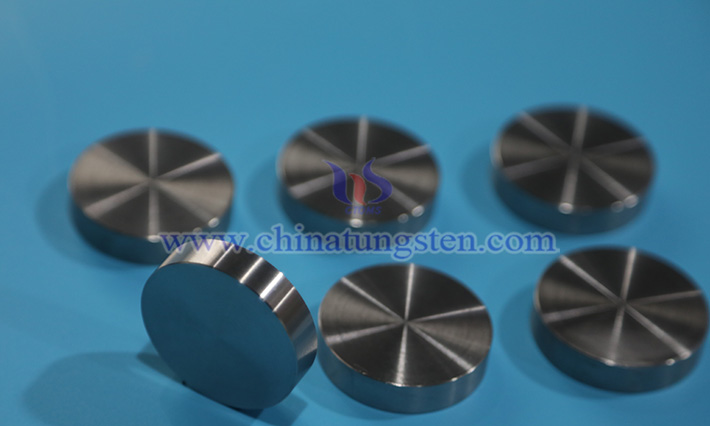

What Is Tungsten Target?

- Details

- Category: Tungsten Information

- Published on Thursday, 11 September 2025 11:31

- Written by Xiaoting

- Hits: 38

Tungsten target materials are typically based on high-purity tungsten, sometimes alloyed with elements such as titanium, tantalum, or nickel to optimize specific properties. As a refractory metal, tungsten features a high melting point and excellent hardness, enabling it to remain stable in high-temperature and high-energy environments. Its body-centered cubic crystal structure provides high density and mechanical strength, allowing it to withstand the intense ion bombardment during sputtering without deforming or fracturing. Additionally, tungsten’s good chemical stability offers excellent resistance to acids, alkalis, and other reactive gases, ensuring long-term stability in complex chemical environments.

Comparison of Tungsten Targets with Other Targets

- Details

- Category: Tungsten Information

- Published on Thursday, 11 September 2025 11:43

- Written by Xiaoting

- Hits: 29

Compared to copper, aluminum, titanium, and molybdenum targets, tungsten targets exhibit significant advantages in high-temperature resistance, high density, chemical stability, mechanical strength, and thin film quality. Their stable performance in high-temperature, high-corrosion, and high-precision sputtering processes makes them the preferred material in semiconductors, medical devices, new energy, and optical coating fields.

Read more: Comparison of Tungsten Targets with Other Targets

Surface Treatment Methods for Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 18:33

- Written by Zhenghua

- Hits: 42

Cemented carbide balls surface treatment can be achieved through a variety of processes, including hard chrome plating, hard alloy overlay welding, plasma nitriding, supersonic spraying, chemical conversion coating, vapor deposition, laser surface modification, and fine grinding and polishing. Different methods focus on improving hardness, wear resistance, corrosion resistance, process complexity, and applicable scenarios. The following are some common surface treatment methods for cemented carbide balls:

Read more: Surface Treatment Methods for Cemented Carbide Balls

sales@chinatungsten.com

sales@chinatungsten.com