Tungsten Electrode MSDS(Part)

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 August 2015 17:56

- Written by Yahong

- Hits: 296

Material Safety Data Sheet (MSDS) is a table about data regarding the properties of a particular substance, which may concern instructions for the safe use and potential hazards associated with a particular material or product. Therefore, MSDS is important and necessary for chemicals users. The sheet aims to offer workers and emergency personnel with procedures for handling or working in a safe way, and includes information such as physical data (melting point, boiling point, flash point, hardness, ultimate tensile strength, density, etc.), toxicity, health effects, first aid, reactivity, storage, disposal, protective equipment, and spill handling procedures. The exact format for MSDS can vary from countries to countries by respective national requirement. For example, below is part of the MSDS of tungsten electrode:

MATERIAL SAFETY DATA SHEET

1. Material Identification

Product name: Tungsten electrode

Manufacturer: ChinaTungsten Online Manu. & Sales Corp.

2. Hazards Data

Danger information: N/A

Particularly dangerous for people and the environment information: N/A

Classification: According to the latest version of the EU classification

3. First Aid Measures

Inhalation: Remove the patient to a place with fresh air. If his breathe is hard, administer oxygen. If not breathing, begin artificial respiration.

If no detectable pulse, begin Cardiopulmonary Resuscitation (CPR) and call for medical aid.

Skin: Wash infected skin with soap and water. If rash occurs, see a doctor right away.

Eyes: Flush eyes with a large amount of fresh water for more than 15 minutes and then seek medical advice.

Ingestion: Go to a doctor.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Composite Tungsten Electrode Application-Ⅱ

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 August 2015 17:55

- Written by Yahong

- Hits: 334

Composite tungsten electrode is an electrode adding two or more rare earth oxides into tungsten, which are complementary to improve their welding performance. Therefore, they become extraordinary in electrode family. There are different standards for composite tungsten electrode. National standard IS06848 and American standard AWSA5.12 are two of them. The surface condition of composite tungsten electrode is glabrous, clean, no default (fissure, palling), no burrs, and no inner defects on the fracture surface and no oil fouling.

Certainly, composite tungsten electrode has other applications.

Nickel-tungsten- composite tungsten electrode in hydrochloric acid solutions

Composite electroplating is developing rapidly which has been widely used in industries. In view of the squandered metal in composite electrodeposits, for example, the squandered nickel in nickel-tungsten-tungsten carbide composite electrodeposits. Nickel-tungsten-tungsten carbide composite electrode can improve effects of the amount of codeposited tungsten carbide particles, temperature and concentration of hydrochloric acid on the anodic behavior of nickel-tungsten-tungsten carbide composite electrode in hydrochloric acid solutions.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Composite Tungsten Electrode Application-Ⅰ

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 August 2015 17:53

- Written by Yahong

- Hits: 303

Composite tungsten electrode applied in welding, which is the same with other tungsten electrode. But they are different in welding industry. Since composite tungsten electrode owns slightness arc, big compression degree, the dissolves depth is biggest during welding at middle and big electric current, they are mainly used to war and aerospace industry.

Composite tungsten electrode in electrochemical catalyzed hydrogen evolution

Composite tungsten electrode can improve the electmehemical catalyzed hydrogen evolution of cobalt electrode. Cobalt – composite tungsten electrode was developed, and its property of electrochemical catalyzed hydrogen evolution can be showed by means of cathodic polarization curves, a. c. impedance technique and SEM. Compared with cobalt electrode, Cobalt tungsten electrode has rough surface, high exchange current density and smaller resistance of hydrogen evolution reaction. But composite tungsten electrode is clean and grounded that superior to cobalt electrode in electrochemical catalyzed hydrogen evolution. Thus, composite tungsten electrode are better choice in electrochemical catalyzed hydrogen evolution.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Composite Tungsten Electrode Manufacturing Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 August 2015 17:54

- Written by Yahong

- Hits: 309

In processing industry of rare earth and high-melting-point metal, swaging apparatus and process for multi-component composite tungsten electrode is a technology.Composite tungsten electrode can be prepared from composite tungsten rod, whose manufacturing process is shown as bellow:

Take Φ6.0 of composite tungsten rod as an example. At the temperature of 1450~1500℃, reducing Φ 6.0 of tungsten rod in a Φ 6.0-Φ 5.6 mold, an then Φ 5.6 of composite tungsten rod is formed. Following the same process, under 1400~1450℃:

1. Reduce Φ 5.6 one in a Φ5.2-Φ4.8 mold

2. Reduce Φ4.8 one in a Φ4.4-Φ4.1 mold

3. Reduce Φ4.1 one in a Φ3.9-Φ3.6 mold

4. Reduce it in Φ3.3-Φ3.0 mold; finally a Φ3.0 of composite tungsten electrode is manufactured.

What mentioned above are procedures of making Φ6 composite tungsten electrode material into Φ3 one. This method can be used to make composite tungsten electrode of other standards.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

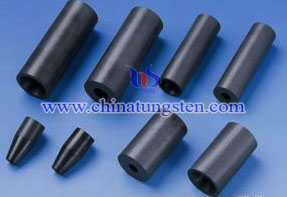

Confining Pressure Influenced Tungsten Carbide Porous Nozzle II

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 August 2015 17:21

- Written by xiaobin

- Hits: 295

Under the lower confining pressure, the velocity of broken volume decrease is faster. However, when confining pressure reaches a certain degree, the decrease scope reduces. With the number of pore increasing, aperture, depth and broken volume will decrease by the rising confining pressure. Different numbers of pores have different sensitivity to confining pressure. On one hand, too many pores will make each flow has little energy, smaller impact area and shorter spraying distance.

On the other hand, the ductility of rocks will promote with the increasing confining pressure, which turns brittle fracture into plastic collapse and all of them will increase the threshold pressure of jet-flow for cracking rock. Therefore, reducing pores appropriately under high confining pressure is beneficial for improving the efficiency of rock cracking.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com