Tungsten Single Crystal Growth Furnace -- Sapphire Glass Artifact

- Details

- Category: Tungsten Information

- Published on Friday, 25 August 2017 11:18

In recent years, sapphire glass seems to be the most hit in the glass world, not because it has the title of "Sapphire", but that it is often publicized on the high-end mobile phone screen.

Some mobile phones claiming to have sapphire glass tend to be tens of thousands. Of course, the true purpose of sapphire glass is to be used as substrate and substrate material for infrared optical materials, electronic devices and high temperature superconducting films.

Sapphire glass is made from synthetic sapphire. Its chemical composition and physical properties are the same as those of natural sapphires. The reason why it is expensive is that it has low production capacity, which is why IPhone6 claims to use sapphire glass but chose to abandoned it at the end.

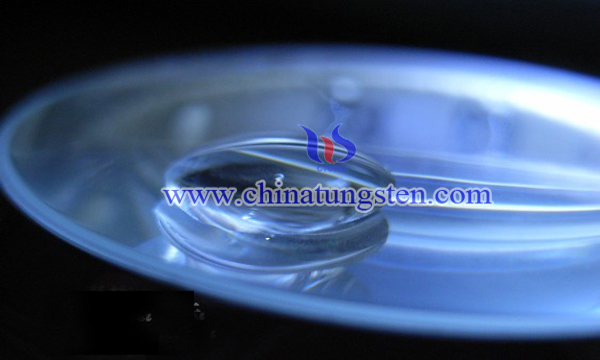

In China 65% of manufacturing enterprises use sapphire kyropoulos method, the key of the kyropoulos method is preparing equipment. The principle of kyropoulos method similar with Czochralski method, which is pulling crystals from the melt of the crucible, in the process of preparation, the crystal bar is firstly contacted with the surface of the fusant, at the solid-liquid interface of the crystal bar and fusant, the crystals begin to grow, and then rotate the crystal bar to slowly pull up the seeds. When the seed crystal forms the crystal neck, the seed will no longer rotate and no longer lift. Finally, the cooling speed is controlled so that the crystal gradually solidifies from top to bottom into a single crystalline patch.

It is understood that the growth of sapphire single crystal alumina raw material melting point of 2045 °C, and is long-term heating, in this case, the test of high temperature equipment such as crucibles is huge, in nature, the melting point of tungsten is 3380 °C, and the melting point of molybdenum is 2620 °C, as a result, it was only tungsten and molybdenum can withstand the high temperature environment. Therefore, the preparation of sapphire glass heating and insulation system basically use tungsten and molybdenum materials. Tungsten is expensive, but its performance is stable, molybdenum is cheaper, but it can also be used. However, as the supporting material contacts the crucible, its high thermal conductivity makes the lower half degree gradient of the furnace body very small. When the liquid level of the fusant decreases with the crystal growth, the temperature gradient will be reversed, and the crystal will easily adhere to the crucible wall, based on this factor, it is recommended to set reasonable quantity of crystal growth and use more stable tungsten material with high temperature resistance and high heat.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com