Shipping Capacity Setting - Ultrafine Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 August 2017 11:46

Hydrogen reduction is the main method for preparation of ultrafine tungsten powder. Its main equipment is multi-tube reduction furnace which is divided to thirteen-tube furnace and four-tube furnace two types.The metal boat – multiple tube reduction furnace - has 3 to 5 vessels for loading containers.

Specific process is that men sequentially load and unload materials, and the excess hydrogen moves into the tubular reducing furnace along or against the direction of the tungsten material, reacting with the material.

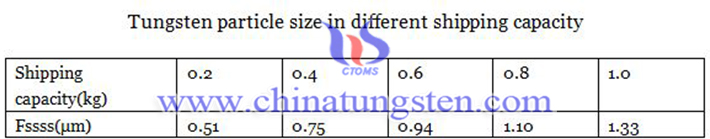

The shipping amount has an impact on particle size of reduced tungsten powder as well. When the loading capacity is large, the thickness of the material layer is increased, and the porosity of the material layer is small, making against the diffusion of water vapor in the reduction progress. Thus the function of tungsten oxide and water vapor increases, which causes the powder to be thickened.

When the loading capacity is larger and the material layer is thicker, the particle size of the prepared tungsten powder is larger. Even when the material layer’s thickness is too large, the hydrogen cannot penetrate the material layer and reaction with the material at the bottom. So excessive ship volume needs to be avoided during the production process of tungsten powder.

However, a thin layer of material will inevitably lead to low production capacity. In order to improve the production capacity, double layer or three layer boat reduction technology is often used in the production process. One or two upper boats placed on the bottom boat improve the reduction condition and the hydrogen can flow between the boat dishes, greatly improving the productivity of ultrafine tungsten powder.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com