Tungsten and Molybdenum Separation - Activated Carbon Adsorption Method

- Details

- Category: Tungsten Information

- Published on Thursday, 06 July 2017 17:21

Tungsten and molybdenum are similar elements, they both belong to VIB clan of element periodic table, have similar property. Tungsten and molybdenum separation has always been a difficult issue in tungsten ore metallurgy, and a key process during beneficiation.

There are several methods include extraction method, precipitation method and ion exchange method to realize the separation. Activated carbon adsorption method is a special method.

Micro electronic technology and photoelectric technology require high purity tungsten. For example, semiconductor line material, tungsten thin film and sputtering target need tungsten powder purity to reach 99.999% or ammonium paratungstate purity to reach 99.999%. Tungsten and molybdenum have similar chemical property, molybdenum is the hardest impurity to be removed during APT producing process. The regular methods can not perfectly promote its purity.

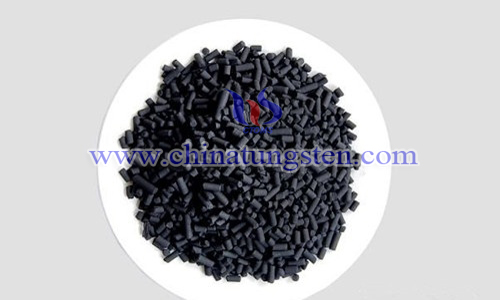

For a long time, scholars from in and abroad have done a lot of researches for tungsten and molybdenum separation. Activated carbon adsorption method developed by specialists from Zhongnan University is used for producing high purity tungsten. It transforms molybdenum into thiomolybdate, using activated carbon as adsorption medium, realize tungsten and molybdenum separation in a process similar to ion exchange method.

Process of activated carbon adsorption method uses activated carbon as adsorption medium. For sodium tungstate solution containing WO3 68.5g/L and Mo 0.144g/L, when flowing rate is less than 2cm/min, aspect ratio of adsorption column is bigger than 14, the flowing solution containing WO3 63.71g/L and Mo 0.0206g/L, molybdenum removing rate is 85.69%. Compared to traditional method, it is simple and the adsorption content is promoted. Due to slow adsorption process of activated carbon, flowing rate of liquid is slow, aspect ratio of adsorption column is big, so it hasn't been widely applied in industry.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com