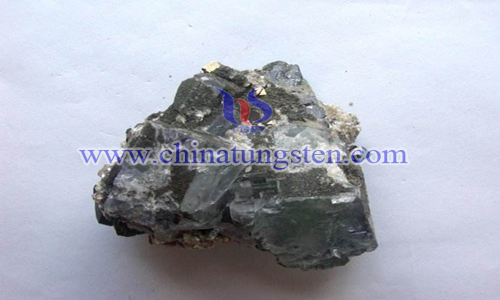

Tungsten Concentrate Selection

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 June 2017 17:40

Tungsten concentrate after gravity separation still has high density minerals such as tinstone, scheelite, molybdenum and bismuth. Quality and purity can not meet standard. So tungsten concentrate selection is needed.

Tungsten concentrate selection is the most complex process in beneficiation, it almost covers all beneficiation methods in gravity separation, flotation, magnetic separation and chemistry to obtain high purity concentrate.

Gravity separation is using jigging, tabling to clear gangue. Flotation uses flotation machine to separate sulfide ore. Magnetic separation is using magnetic separator to separate scheelite and tinstone. Electric separation is to separate tinstone and rare earth element. Phosphorite, calcium element in concentrate can be dealt with acid doping method, arsenic element can be calcinated by oxidation.

Tungsten concentrate usually uses flotation – gravity separation method or flotation – gravity – magnetic – electric method for beneficiation. Most of them uses discontinuous mode and decide the next step based on reality. Recycle of accompanied element is also in selection process. The valued elements are tin, molybdenum, bismuth, copper, lead, zinc and sulfide. Recycle them can not be neglected in selection process. It is key to earn more profit. In China, many mining enterprises can only cover basic expense, accompanied elements can bring profits on the contrary.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com