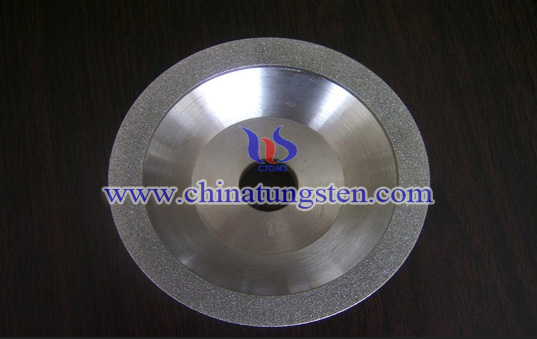

Tungsten Carbide Grinding Wheel

- Details

- Category: Tungsten Information

- Published on Wednesday, 31 August 2016 18:12

Tungsten carbide grinding wheel is a kind of consolidated mold with high hardness, high strength, excellent wear resistance and can be used in metal or nonmetal milling and cutting process.Tungsten carbide grinding wheel is composed of WC and Co binder, and the structure includes grinding compound, binder and pore. In the course of work, the high-speed rotation of tungsten carbide grinding wheel can used for flat, outer, inner surface of in metal or nonmetal coarse milling, semi-finishing, finishing.

The main specifications of the grinding wheel include the abrasives, the granularity, the hardness, the binding agent, the shape and the size, etc. It can be divided into ordinary abrasive (corundum and silicon carbide) grinding wheels and natural abrasives, super-hard abrasive (tungsten carbide, diamond and cubic boron nitride (CBN)) grinding wheel according to the types of abrasives; flat-shaped grinding wheel, bevel wheel, cylindrical grinding wheel, cup wheel, disc-shaped wheel from different shape; and ceramic wheel, resin wheel, rubber wheel and metal wheel depends on the different binder.

The abrasive granularity can be divided into particles (>40μm) and powders.

|

Particle |

Powder |

||||

|

Granularity |

Size (μm) |

Granularity |

Size (μm) |

Granularity |

Size (μm) |

|

14# |

1600-1250 |

70# |

250-200 |

W40 |

40-28 |

|

16# |

1250-1000 |

80# |

200-160 |

W28 |

28-20 |

|

20# |

1000-800 |

100# |

160-125 |

W20 |

20-14 |

|

24# |

800-630 |

120# |

125-100 |

W14 |

14-10 |

|

30# |

630-500 |

150# |

100-80 |

W10 |

10-7 |

|

36# |

500-400 |

180# |

80-63 |

W7 |

7-5 |

|

46# |

400-315 |

240# |

63-50 |

W5 |

5-3.5 |

|

60# |

315-250 |

280# |

50-40 |

W3.5 |

3.5-2.5 |

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com