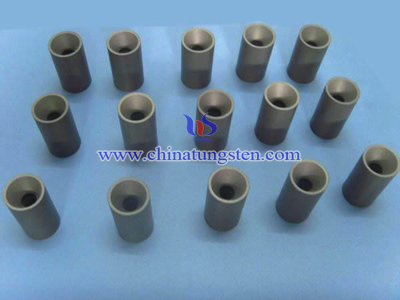

Tungsten Carbide Nozzle Used for Sand-blasting

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 August 2016 16:20

Sand-blasting treatment is also called shot peening treatment, is a kind of workpiece surface treatment process that powered by compressed air, the beam through the high-speed jet spray material (such as the common copper sand, quartz sand, silicon carbide, iron sand, sea sand, etc.) to the high-speed jet processing workpiece surface. During the process, the surface or the shape of the workpiece has been changed by the cutting and impacting action and obtain certain roughness and cleanliness. Furthermore, the sand-blasting process also improves the mechanical properties and fatigue resistance, which also enhances the binding force and durability of the coating layer and is beneficial for the leveling and decoration of the coatings.

At present, sand-blasting process widely used in mechanical rust removing and polishing. And the sand-blasting equipment used includes inhaled dry blasting machine, pressure-blasting machine dry or liquid blasting machine. Regardless of what type of blasting equipment, tungsten carbide nozzles are the one of the essential components. Compared with other materials, such steel nozzle, tungsten carbide nozzle has higher hardness, higher strength and better performance in wear and corrosion resistance. But there are two problems in the sand-blasting process. One is difficulty in sand suction caused by the poor vacuum degree of inlet wet sand and the small inlet diameter; the other is within the blowhole water mixed with sand from the entrance to the straight pipe does not match or sand mixed with water nozzle wear inappropriate material selection problems caused by straight pipe. So the main criteria used to judge carbide blasting nozzle includes material selection, the length of the diameter of the sand suction tube diameter, the diameter of the blowhole sand-water mixture from the straight pipe sections and other factors. In addition, in the sandblasting process, pay attention to controlling the distance well nozzle and the workpiece, and the position of the welding time control to eliminate the residual stress of the welding surface. And corrosion inhibitors can be added to a mixture of water blasting process to prevent the secondary oxidation of metal surface.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com