Tungsten Carbide DTH Drill Debris Removal System

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 July 2016 15:01

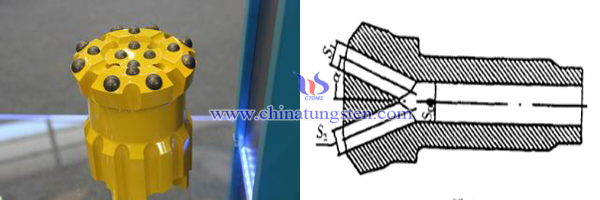

Tungsten carbide DTH drill is composed of steel base, shank and participation nylon tube, tungsten carbide buttons and debris removing system. In the high-frequency impact and continuous scrap of tungsten carbide buttons, it will produce some small debris. If the debris piles up, the wear of buttons will be aggravated and has a bad effect on the service life and the drilling efficiency. So the debris removal system of tungsten carbide DTH drill is significant, which consists of tail hole of drill, top blow hole and the debris removal groove. The top blow hole and the tail hole have staggered structure, design on the top side of the hole location, number and size of the diameter of a hair spray angle holes, need to consider the size of the drill diameter, working pressure, oxygen consumption and tail hole diameter and other factors, the top surface of the hole and the various elements of the hair there is a certain relationship of matches. This structure is equivalent to drill fitted with a tail gas unit, help to make up for the energy and high-pressure air pressure loss in the pipe during operation, the high pressure high speed airflow blown from the hole, which will help drain slag debris.

The injection angle of the blow hole is the included angle of the axis of the injection hole and the center axis, which increases with the increasing pressure. The experiment shows that the higher working pressure, high-pressure air and high-pressure air is blown rock debris or cuttings cutting surface moving ever closer to the rock, rock dust or debris promptly blow hole bottom, spray angle values are generally larger. If high pressure, spray angle is small, the dust were blowing at high pressure gas flow through the bottom of the hole reflected the majority of dust affixed to the surface of the steel drill bit head run, badly worn, bare and likely to cause the intermediate button fracture, drill early failure, reduce the service life of the drill. In addition, the depth of the debris groove chooses according to the working pressure, the rock hardness, higher working pressure or higher the hardness of rock powder discharge groove depth can be relatively reduced.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com