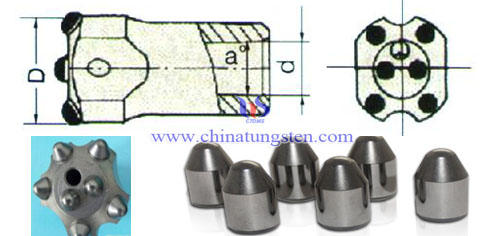

Tungsten Carbide Button Used for DTH Drill

- Details

- Category: Tungsten Information

- Published on Monday, 04 July 2016 15:38

DTH drill uses compressed air as a power source to drive DTH hammer piston, and high frequency impact DTH drill by large impact energy. At the same time, the axial pressure and rotary torque effect from drilling bars rotate and break the rocks. The debris they produce high-pressure air is carried back to the earth surface. This kind of DTH drill has many advantages, such as high drilling efficiency, high quality of drilling, long service life of drill bits, not easily to be blocked and low cost, which as a kind of efficient drilling process and has been widely used in Mine blast, geological exploration, hydrology well drilling and other drilling purposes, especially effective in medium hard and hard formation. However, tungsten carbide buttons used for DTH drill directly affects DTH drill performance. Since in the process of drilling, the button under the action of high-speed impact of high frequency impact energy to hit the rocks, resulting in a larger volume breaking, DTH drill has higher efficiency. In addition, tungsten carbide buttons crush rock is a dynamic, non-linear failure process, which can be divided into 3 steps:

1. The moment of button and rock contacting, the load is small and rock has elastically deformed, and it appears a hemispherical elastic region under the button;

2. The buttons move down continuously, the load and the elastic region increases, the stress wave uses the point of button and rock contact as the center of the sphere, concentric spherical shape continuously to spread inside the rock. Meanwhile, it appears a high-stress area under the contact point of button and rocks. When the stress reached the limits of zone status, rocks were fractured;

3. The buttons intrude the rocks further, pressure on the surrounding rock to the side and gradually increased, eventually collapse from the surrounding rocks, forms a large volume of crushing, crushing cavity is formed.

In general, DTH drill uses 9 buttons, the bottom surface 3 by a clockwise spiral arrangement, other 6 edge evenly distributed. The bottom sets 3 buttons to ensure that each button can endure the largest impact energy, and the closest to the center uses inlay welding process, which is beneficial for coring. The other 6 edge buttons play a role in holding aperture and breaking the rocks surrounded.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com