Tungsten Bronze Structure Materials Application in TBC

- Details

- Category: Tungsten Information

- Published on Thursday, 19 May 2016 17:50

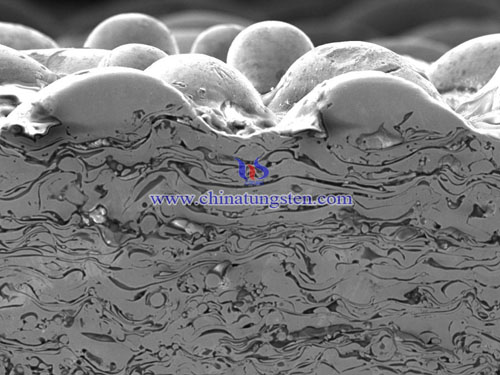

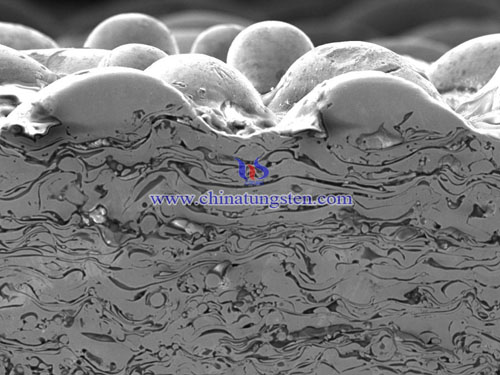

Thermal barrier coating (TBC) system has been widely applied in the first and second rows of turbine blades and combustion chamber components exposed to the hot gas path of the gas turbine. Typically, the yttria-stabilized zirconia thermal barrier coating is widely applied to the high temperature section, to provide a thermal mechanical shock, high temperature oxidation and hot corrosion damage protection.

The initially main purpose of providing TBC is to extend the life of the coating components, but advanced gas turbines makes more and more use of the TBC to improve the efficiency and power output of the gas turbine. A means of improving the efficiency and power output is to reduce the consumption of hot gas path component cooling air, even if those components are capable of operating at higher temperatures. Requirements for higher combustion temperature and reducing cooling flow produced a constant demand for advanced TBC to have higher temperature stability and better insulation in order to achieve long-term efficiency and performance targets of advanced gas turbine.

By using the tungsten bronze structure ceramic coating material with a lower overall thermal conductivity to improve insulation of TBC. Usually these structures have excellent thermal, physical and mechanical properties. Combination of big complex cell and strong anisotropy atomic bonds and with high atomic weight, making them an ideal target with lower thermal conductivity. In addition to the thermal - mechanical properties, the new TBC also showed excellent relative stability in the operating temperature range and increasing anti-sintering properties in extreme environments in the turbine section. In addition, they are compatible with traditional or new adhesive layer and super alloys.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com