Tungsten Copper Liner Explosive Sintering (1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 May 2016 16:09

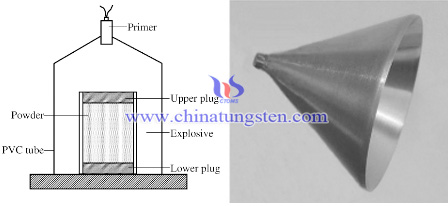

In today's highly modernized military industry, a growing number of armored tanks, armored vehicle equipped with reactive armor has a very high anti-missile capabilities, which also brings the corresponding anti-armor weapons a more serious challenge. The combination of shaped charge and precision guidance is the most effective anti-armor weapon, and the liner is key component of the shaped charge and carrier of shaped, whose performance will directly affect the density, the speed, the length of continuous jet, penetration depth and armor performance. Theoretically, it requires tungsten copper liner has higher density, excellent ductility, which can ensure that the jet can be stretched without fracture before the penetration. Conventional powder liner materials include copper, steel, tantalum, tin and so on, but due to the single material can not meet the various properties requirements today, the composite liner appears.

Compared with liner with single material, composite liner combines different properties of metals or alloys and designs according to the liner to show the advantages of them, which has higher energy efficiency, higher energy conversion efficiency, more reasonable absorption mechanism and excellent armor performance and it is a new trend of liner development. Multi-phase composite liner commonly used are W-Cu, Ta-Cu, Re-Cu system, and wherein the tungsten copper W-Cu overall performance of the most prominent performance-related Liner are the best matches. Tungsten copper alloy is Cu difference between two kinds of physical and chemical properties of W and face-centered cubic structure of the body-centered cubic structure is neither large nor the formation of pseudo alloy intermetallic compounds. It not only has high hardness, high strength, high density, low thermal expansion coefficient and excellent abrasion resistance of W and also has plasticity and excellent electrical and thermal conductivity of Cu. Tungsten jet head with a higher speed, when penetrating armor can shorten the time through, thereby facilitating against reactive armor. But it is brittle and the powder adhesion is poor, the added copper powder with good ductility can contribute to the shaping process and improve the jet stability, avoid breaking.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com