WO3 Prepares Non-Supported Desulfurization Catalyst - Urea Melting Reaction Method

- Details

- Category: Tungsten Information

- Published on Monday, 09 May 2016 17:17

Urea melting reaction method is mixing the precursor metal components and urea, reacted in a molten state urea to remove excess urea to obtain the catalyst particle with nano-pores and high specific surface area. The example that using urea melting reaction method and taking tungsten trioxide as raw material to prepare non-supported desulfurization catalyst is as following:

Urea melting reaction method is mixing the precursor metal components and urea, reacted in a molten state urea to remove excess urea to obtain the catalyst particle with nano-pores and high specific surface area. The example that using urea melting reaction method and taking tungsten trioxide as raw material to prepare non-supported desulfurization catalyst is as following:

1. Weight tungsten oxide, molybdenum trioxide and basic nickel carbonate by the molar ratio of tungsten: molybdenum: nickel is 1: 1: 2;

2. Add an appropriate amount of urea to the three-necked flask, besides, a small amount of water is added to disperse it evenly, then place it in an oil bath at 130° C to react for 4 hours with stirring, and then pour it into a tray to cool down when the reactants are hot;

3. Crushing the cooled products with a pulverizer, drying in an oven at 150° C and decomposing the excess urea at the same time;

4. Weight the appropriate amount of quasi-boehmite; add dilute nitric acid solution to form an aluminum sol, and then pulverized solid active ingredient to mix into paste, finally we get the strip products with a diameter of 1.6mm by kneading, extruding;

5. Drying for 5h under the infrared lamp and in an oven at 110° C for 10 hours, calcining in a muffle furnace at 400° C for 5 hours to form the non-supported desulfurization catalyst.

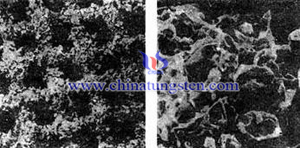

This non-supported desulfurization catalyst itself has nano-pores and the higher specific surface area, which can provide a wealth of catalytic hydrogenation active sites, thus having a high hydrogenation activity. It can be used in the ultra-deep hydrotreating of light, medium and heavy distillate oil. Meanwhile, the urea melting reaction method with the raw material of tungsten trioxide to prepare non-supported desulfurization catalyst is simple, easily operated, response fast and suitable for industrial mass production, is a method with good prospects for development for producing catalyst.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com