Sodium Tungsten Bronzes Single Crystal Growth

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 May 2016 18:28

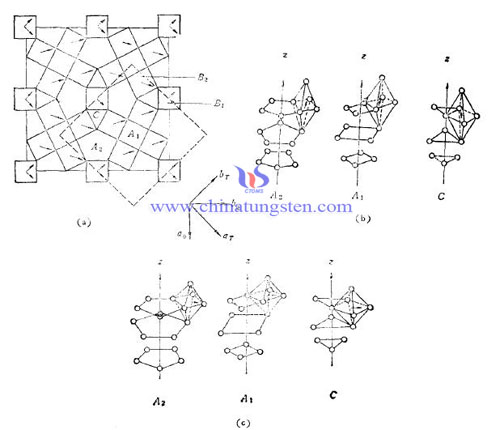

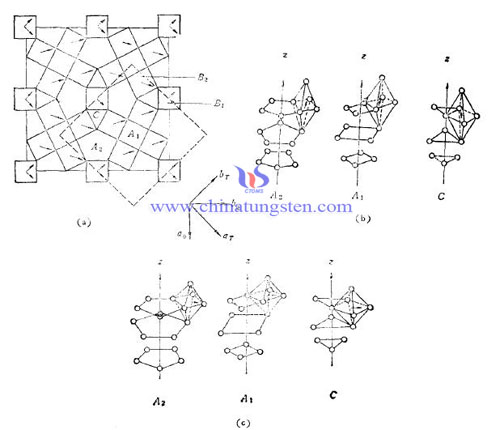

An investigation into the growth of large single crystals of the sodium tungsten bronzes was initiated in order to obtain suitable samples for conductivity measurements.22 The use of tin metal to reduce a tungstate melt' was investigated. For this purpose, tin was placed in a non-porous porcelain tube and covered with a column of sodium tungstate. A layer of tungsten(VI) oxide was added at the top, so it could diffuse slowly to the reaction surface, and the tube placed in a vertical tube furnace at 750°. The largest crystal obtained measured 8.8 × 8.0 × 7.9 mm. However, on cleaving this sample, it proved to be an oriented polycrystal. In general, crystals grown by this method contained occluded material and reduction products such as tin oxide, and the use of this method was discontinued.

The recrystallization of sodium tungsten bronzes from molten sodium tungstate yielded smaller crystals than the tin reduction method. Although the crystals obtained were free of occluded tungstates and tin oxides, they contained some metallic tungsten and had a tendency toward excessive twinning, even with slow cooling from 1100 to 700 over a period of days.

A study of electrolytic reduction methods was made, and suitable crystals up to 12 mm. on an edge were grown. A mixture of sodium tungstate and tungsten(VI) oxide in a porcelain crucible was fused and electrolyzed (platinum electrodes) at an e.m.f. of 4.0 volts, with the cathode at the bottom of the crucible. The ratio of sodium tungstate to tungsten(VI) oxide was varied. The current density at the cathode was varied between 0.025 and 0.76 amp./cm.2 and the temperature was kept constant between 750 and 850°. Some qualitative conclusions can be drawn from the data. The sodium content of the resulting bronzes increases with increasing ratios of sodium tungstate to tungsten(VI) oxide. Both the size of the crystals and their perfection seem to be improved with lower current density or higher temperatures.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com