Reasons for the Crack of Tungsten Crucible Bottom

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:30

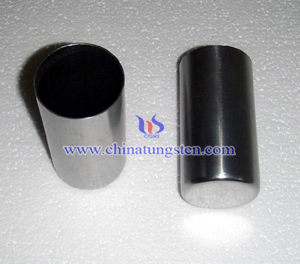

As the main tungsten product, tungsten crucible is widely applied in smelting of rare earths and the demand of it is also increasing for rare earth industry. However, the crack of tungsten crucible bottom will directly influence in the rate of finished tungsten crucible products during the productive process. Operating engineer should pay attention to the reasons for the crack of tungsten crucible bottom and find out the solution to solve those problems, so that the rate of finished tungsten crucible products can be improved. According to researchers, they show that reasons for the crack of tungsten crucible bottom mainly lie in the pressing step and sintering step.

During the pressing process, if people select the thicker tungsten powder which would be difficult to suppress. It would result that the pressed compact higher needs a higher sintering temperature or more holding time in the next step sintering. What’s more, the thicker tungsten powder would waste much energy and time and has a great impact on the life time of the equipment. In the selection of the powder, in general, the thicker the tungsten powder is,the worse the compressibility is. And it would cause that users should choose a more large size of the mold cavity while filling it. A large powder needs for more pressure during the pressing. Except that, its compression is poor and it would directly reduce the density of the pressed compact. Therefore, when choosing the size of the powder, users should choose different sizes. The small size particles can fill the space leaving by large particles in the process of pressing to increase the density of compacts to avoid being cracked. In addition, the pressure of the pressing process also affects the qualified rate of the tungsten crucible compacts. Moreover, the qualified rate of the tungsten crucible compact is also affected by the hardness of the rubber sleeve, the greater the hardness, the more likely cause cracks.

During the sintering process, the selection of equipment and the sintering atmosphere has a greater impact on the qualified rate of the tungsten crucible. It’s required that tungsten crucible should be under a anaerobic condition, but there still exist oxygen on the surface of tungsten powder, the oxide film of its surface would hinder the sintering process. Oxygen of tungsten powder will be greatly removed in a hydrogen atmosphere which would increase the density of the product. In the selection of the sintering equipment, electric resistance furnace would be better than the induction furnace. The temperature of the upper and lower ends of the induction furnace is much lower than the middle part because of its structure, which would result in nonuniform sintering of tungsten crucible bottom.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com