Defect of Tungsten Trioxide SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 April 2016 17:44

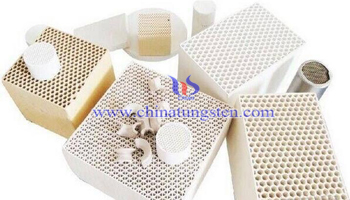

SCR denitration technology has been used in coal-fired power plant for 30 years; it stands out as the efficient flue gas denitration technology, which is a reliable method of denitration. SCR technology can be divided into the three types of high (greater than 400°C), medium (among 300~400°C) and low (less than 300°C) temperature catalyst depending on the reaction temperature. Although tungsten trioxide SCR denitration catalyst is the most mature technology which has been constantly research, it still has a lot of defects.

SCR denitration technology has been used in coal-fired power plant for 30 years; it stands out as the efficient flue gas denitration technology, which is a reliable method of denitration. SCR technology can be divided into the three types of high (greater than 400°C), medium (among 300~400°C) and low (less than 300°C) temperature catalyst depending on the reaction temperature. Although tungsten trioxide SCR denitration catalyst is the most mature technology which has been constantly research, it still has a lot of defects.

1. The temperature required being above 350°C, in this environment the sulfur dioxide can avoid to be oxidized to sulfur trioxide, thus weakening the influence of denitration activity. So, SCR denitration catalyst is required to be square at the top of between the desulfurization and dust, which is conducive to utilizing the flue gas heat, otherwise it requires additional air preheater and cause more energy consumption.

2. The catalyst plugging. When the flue gas through the catalyst, the generated salts and fly ash will block the catalyst, thus to result in catalyst warn and even affecting the purification efficiency.

3. Wearing catalyst. Fly ash in the flue gas significant wears the catalyst during high-speed operation.

4. The catalyst poisoning. Alkaline metals such as Na, K and toxic impurities As will cause catalyst poisoning, thus affects adversely to the catalyst activity.

5. The air preheater clogging, corrosion. Vanadium pentoxide has function that oxide the sulfur dioxide to sulfur trioxide, we all know that the sulfuric acid will generate when sulfur trioxide meets with water which will corrode the downstream pipeline; in addition, the slipping ammonia in the denitration reaction can react with sulfur trioxide to generate the ammonium sulfate which is adhesive and corrosive, thus to cause the air preheater heat transfer surface clogging or corrosion.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com