The Detection of Carbon and Sulfur of EMM Only by Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 April 2016 16:47

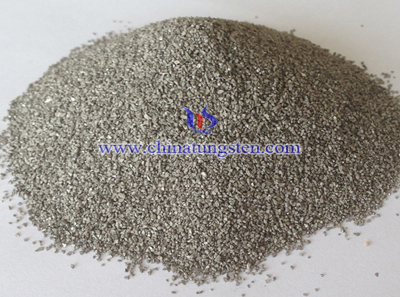

The full name of EMM is electrolytic manganese metal. EMM has a high purity and it can increase the hardness of the metal materials. Tungsten granule is mainly applied to Carbon sulfur analyzer to analyze the content of carbon and sulfur. To analyze by tungsten particles is a much simpler way. Manganese metal is a kind of metal with a silvery-white color. On the other hand, manganese is hard and easy to be oxidized at an elevated temperature. The metal manganese is widely distributed in nature and the number of manganese is the three-ten thousand of the total number of atoms in the earth’s crust.

For traditional ways to detect the content of carbon and sulfur of manganese metal, the choice of flux include the following types: pure iron and tungsten granule, tin particles and tungsten granule, pure iron plus tungsten granule plus tin particles. The operator cannot control the number of flux well while operation from the three types. If the amount of flux is too much, it would make the samples splash easily or produce dust while burning. If the amount of flux is too less, it would not burn fully, both will have a great impact on the results of the analysis.

Operator selects standard samples of manganese metal and tungsten granule to detect for 3-5 times, and the repeatability of the result will be better. Operator selects a common electrode sample and a high manganese sample, puts about 0.35g of manganese metal specimens in a crucible uniformly, and covers about 1.5g of tungsten granule uniformly to make the analysis. And then, the result of relative standard deviation is less than 5%. It shows that the determination of carbon and sulfur of EMM only by tungsten granule has a very high precision.

Consider tungsten particles as a flux to detect the content of carbon and sulfur of EMM not only can reduce the cost of sample analysis, but also can greatly improving the work efficiency. In addition, the operation of this method is simple.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com