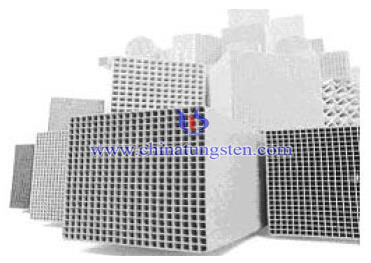

MnOx/WO3/TiO2 Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 April 2016 16:16

The better reacting temperature of tungsten trioxide SCR denitration catalyst is about 300~400℃, however, it is no way to achieve this range in the general factory; therefore, the flue gas should be heated by the GGH or burners in the denitration process, thus cause the energy consumption and operating costs increased. So, it is imperative to reducing the suitable temperature of denitration catalyst and improving its property. Studies have pointed out that MnOx/WO3/TiO2 denitration catalyst can carry out NOx removing in a lower temperature by adjusting the content of tungsten trioxide and reaction environment, which is a good low-temperature denitration technology.

The better reacting temperature of tungsten trioxide SCR denitration catalyst is about 300~400℃, however, it is no way to achieve this range in the general factory; therefore, the flue gas should be heated by the GGH or burners in the denitration process, thus cause the energy consumption and operating costs increased. So, it is imperative to reducing the suitable temperature of denitration catalyst and improving its property. Studies have pointed out that MnOx/WO3/TiO2 denitration catalyst can carry out NOx removing in a lower temperature by adjusting the content of tungsten trioxide and reaction environment, which is a good low-temperature denitration technology.

The steps of one-step-impregnation method to prepare MnOx/WO3/TiO2 denitration catalyst are like bellows:

1. Prepare titanium dioxide for further using;

2. Dissolve an amount of ammonium tungstate solution into the oxalic acid, then add a certain amount of manganese acetate, and add the carrier--titania under stirring to obtain a mixed solution;

3. Stir the mixed solution uniformly obtained in step 2 at 35℃ for 2 hours, and then immersed with stirring by heating to 85℃ for 4 hours, then dried at 110℃ for 12 hours;

4. Transfer the powder into a muffle furnace after ground to calcine at 450℃ for 3 hours, to generate the needed MnOx/WO3/TiO2 denitration catalyst.

Experimental results show that the temperature window of this catalyst reaches 80~240℃, thus to greatly reduce the reaction temperature; at the same time, appropriate tungsten trioxide added can significantly improve the catalytic activity, but too much or too little can cause activity decreases, and the excess tungsten trioxide will even reduce the low-temperature activity, but instead increase the activity of MnOx supported catalyst; in addition, the presence of oxygen will promote the oxidation of NO, and protect of the catalyst surface oxidation activity center at low temperatures, thus to facilitate ammonia absorption and activation.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com