Effect of Molding Process on Tungsten Copper Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 January 2016 17:10

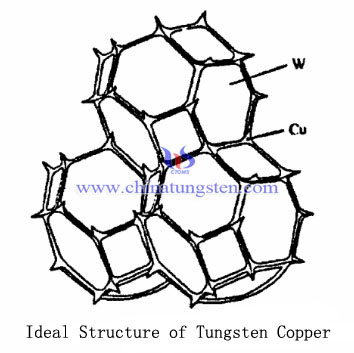

The research shows the ideal structure of tungsten copper composite material has higher density, tungsten particles uniformly dispersed to form a continuous skeleton, and solidified around between copper tungsten particles (including space charge sintered base of the throat gap), a continuous distribution network, and the ideal organizational structure below shows tungsten-copper composite material.

Coefficient of thermal expansion (CTE) is determined by tungsten skeleton. Copper with net structure is stable, which has high density and promote thermal conductivity (TC). Therefore, tungsten-copper composite material densification not only affect the strength of the material, but also directly or indirectly determine the number of other properties of the material, which makes critical study of the sintering process and the molding process of change. In addition, in the process of sintering, many process parameters plays an important role in the density of tungsten copper electrode, such as powder properties, the pressure, the temperature, heating/cooling rate, holding time, lubricant and so on.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com