Soda Thermal Decomposition Scheelite to Produce Sodium Tungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 December 2015 09:04

More than 20 kinds of tungsten minerals have been discovered in the nature. But wolframite and scheelite have the value of industrial research. Scheelite is the main raw material of tungsten smelting. The traditional industrial production technology of disposing scheelite requires a high alkaline, high temperature and high pressure leaching technology to achieve a better decomposition rate. At the same time the leachate contains a lot of alkali salts and the impurity ions. So a large amount of industrial waste water containing salt was produced. Therefore, it is imperative to improve the existing production process.

This article introduced a novel process to separate tungsten from gangue material to produce sodium tungstate with high purity, in which the sheelite was used as feed and the flowsheet was dry ball milling activation一roasting一high temperature smelting with slag former adding. The main research work included directly high temperature smelting and ball milling activation一roasting一high temperature smelting. The experimental methods can be divided into three steps in total:

2. The research of soda roasting of sheelite. The results showed that under the conditions: roasting temperature was 595℃,reaction time was 2 hour, alkali additive amount was 2.3 times of theory stiochemistry consumption, the sheelite decomposition ratio reached 93.79%. Adding quartz had a negative effect on decomposition.

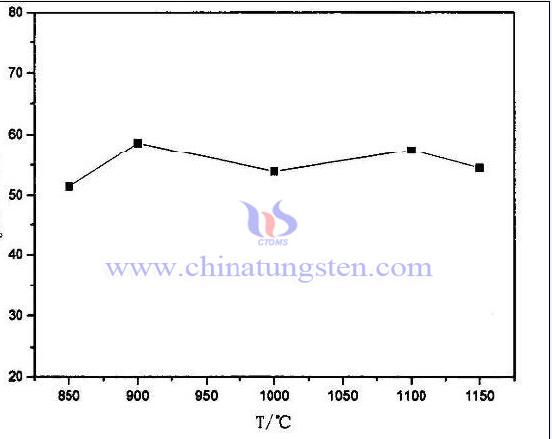

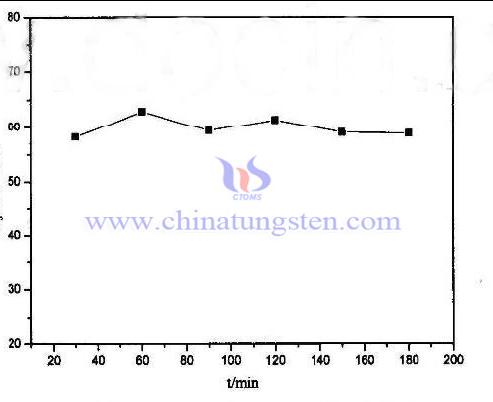

3. The high temperature smelting. Without adding of slag formers, the smelting results showed that the separation of sodium tungstate and slag was very difficult only by increasing smelting temperature(from 1100℃to1500℃). With adding of slag formers, the results showed that the decrease of Ca0 ratio in slag former and the increase of temperature could improve the property of slag and effectively separate slag and sodium tungstate. The addition of sodium floride can not obviously improve the srnelting property.

Melting temperature of scheelite decomposition Melting time of scheelite decomposition

In conclusion, the process of dry ball milling activation一roasting一high temperature smelting with slag former adding, not only effectively decompose scheelite (the decomposition ratio was above 98%), but also produce sodium tungstate with high purity through effective separation of tungsten from gangue. T'he purity of sodium tungstate (include sodium molybdate) was above 94%. Molybdenum cannot be separated from tungsten in decomposition and smelting. The residue can be reused for roasting and smelting.

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com