Preparation of Tungsten Trioxide Thin Tilm 2/2

- Details

- Category: Tungsten Information

- Published on Friday, 25 December 2015 16:53

DC magnetron sputtering deposition of tungsten trioxide thin film on ITO conductive glass, oxygen partial pressure, sputtering power, composition and morphology influence electrochromic properties of temperature on single-layer structure of tungsten trioxide films. In order to optimize the performance of electrochromic thin films, monolayer film according to research results, based on a single-layer film of tungsten trioxide films were prepared by two-layer structure, studied film morphology of the films of the electrochromic properties of the composition. X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), atomic force microscopy (AFM), UV - visible spectrophotometer, electrochemical workstation variety of testing methods, the composition of the film, morphology, spectral and electrochemical properties were analyzed. The results show that tungsten trioxide films prepared under different sputtering conditions are non-stoichiometric ratio (O / W <3). The higher oxygen partial pressure, the tungsten trioxide films prepared O / W increases. When the oxygen partial pressure of 85% tungsten trioxide thin films having more excellent electrochromic properties.

Study results show that the sputtering power in the range of 50W ~ 100W, the sputtering power, density and roughness of the film increases. Appropriately increasing the sputtering power can improve the performance of electrochromic thin films. At room temperature, oxygen partial pressure of 85%, power 100W amorphous tungsten trioxide film microstructure when 120W prepared and have significant differences, and have good electrochromic properties. The maximum change of the transmission before and after coloring the tungsten trioxide films were 74% and 86%, coloring / bleaching response time was 9.6s / 2.9s and 9.3s / 3.9s, coloration efficiency were 45.07cm2 • C-1 and 43.11cm2 • C-1. Single nanometer tungsten trioxide film transmittance modulation capability and efficiency of the structure of the coloring preparation have reached a higher level to meet the requirements of adaptive camouflage.

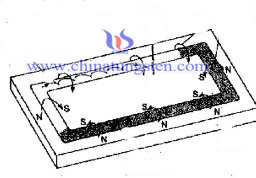

Trajectory magnetron sputtering target surface magnetic field and electron.

Tungsten trioxide film at 350 ℃ Sputtering is monoclinic state, improve the sputtering temperature lowered in the film O / W. After 200 cycles, the stability of crystalline tungsten oxide film may reach 99%. On the basis of a single-layer film structure study prepared three different structures and two-layer structure consisting of tungsten trioxide films, test results showed that: the film morphology and composition will directly affect the performance of electrochromic thin films. Bilayer sample preparation, the upper loose dense lower layer structure electrochromic thin film electrochromic best performance. Loose structure facilitates the diffusion of ions, to improve the response time of the film; a dense structure can improve ion storage capacity of the film. The kind of two-layer structure cycle stability tungsten trioxide films, the transmittance changes, coloring efficiency, coloring / bleaching response time was 84%, 74%, respectively, 19.86cm2 • C-1 and 64.6s / 99.7s.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com