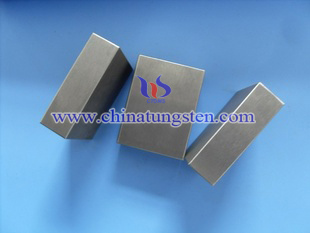

Tungsten Alloy Ballast WeightsⅡ

- Details

- Category: Tungsten Information

- Published on Friday, 18 December 2015 17:46

Tungsten alloy is able to become the first choice of ship ballast weights material , primarily because of its own great advantages.

1, High density

The density of tungsten alloy is up to 18.5 g / cm3, 65% higher than the density of lead alloy. Nowadays, because of its defects, lead has faded away from people’s views, the density of steel and iron or other materials were lower than tungsten alloy, therefore, tungsten alloy can well take over this position and become the preferred weights material that used in various fields.

2, Good wear resistance, corrosion resistance

It is well-known that tungsten has a high density, and it’s a heavy material, it can keep no deformation even at a very high temperature or strong impact, so it’s suitable for long-term immersion in seawater, and also particularly suitable for ballast weights.

3, No environmental pollution

Since using lead material to produce ballast weights, or seawater ballast weights etc, would causes environmental pollution and abuse, but tungsten alloy is a green metal material, it won’t produce toxic substance during producing and processing. Thus, tungsten alloy weights is the most suitable for the ballast weights.

In addition to the above advantages, tungsten alloy also has other series of excellent physical and mechanical properties of good machining, welding characteristics, and can adapt to the dynamic or static installation. It applies not only to the ship's ballast weights, but also applied to the counterbalance weights components of a variety of instruments and engines. Such as the counterweight element on the "Spey" engine and counterweight element for controlling the Sub-throttle of fuel amount adjusted at a high speed and so on.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com