Mechanism of Tungsten Copper Electrode for EDM

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 November 2015 17:23

Electrical Discharge Machining (EDM), in the process of machining, produces discharging spark between the tool and the work-piece constantly, which remove the material depends on part of high temperature. EDM has many advantages, such as it can be suitable for some super-hard material cutting (tungsten carbide, cubic boron nitride, HHB), and it has high machining precision.

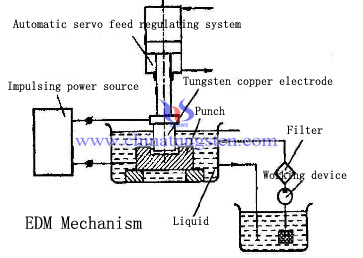

The mechanism of tungsten copper electrode for EDM:

In the process of machining, impulsing power source linked with tungsten copper electrode and work-piece. Generally, the liquid has insulativity (such as kerosene, mineral oil). Tungsten copper electrode is controlled by automatic servo feed regulating system, which ensures the discharging gap (0.01-0.05mm). When the impulse voltage exerted between two electrodes, the liquid medium will be punctured and form discharging channel. The part high temperature melt the material and tungsten copper feed regularly so that the work-piece will be machined as request.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com