Introduction to Tungsten Carbide Burrs

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 September 2015 17:58

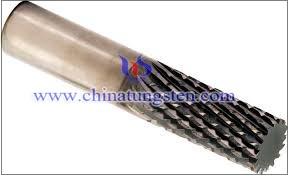

Tungsten carbide Burrs, are burrs made of tungsten carbide, also known as rotary files which consist of small and large shaped cutters used in die grinders, rotary tools, and dentist drills. The name may be considered suitable when their mini-size head (3 mm diameter shaft) is closely similar to that of a seed in the burr fruit. Tungsten carbide burrs are also used in CNC machining robot type centers for removing burrs (the small flakes of metal) after a machining process (burrs-cutting). To sustain the right external speed and cutting environment they are rotated at the maximum velocity achievable, appropriate with their size and structure.

In engineering, a burr can be described as the raised circumference on metal. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion on a surface, after being struck a blow from an equally hard or heavy object. Specifically, burrs are as a rule useless residual that is the effect after machine grinding, drilling, milling, or turning. In the following report the word, burr, refers to the excess substance of material and carbide burr refers to the tool that removes the excess material.

De-burring:The process of removing burrs, the small flakes of metal, is known as de-burring. Burr creation in machining accounts for a major part of the costs for manufacturers throughout the world. Drilling burrs, for example, are common when drilling almost any material. The Boeing 747 airplane has approximately 1.3 million holes drilled in it most of which have to be de-burred to some extent (Burrs-metal, April 2007). As one could imagine, the cost and time needed to perform these drilling and de-burring operations is significant.

In addition to drilling, milling is also a source of burr formation in machining. A good example of unwanted burrs is in the automotive industry where cylinder blocks, pistons and other engine components are cast then milled to a specific dimension. With higher demands placed on accuracy and precision, burr formation is of critical importance because it can affect engine performance, reliability, and durability。

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com