The Metallographic Testing Steps of Tungsten Points

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:26

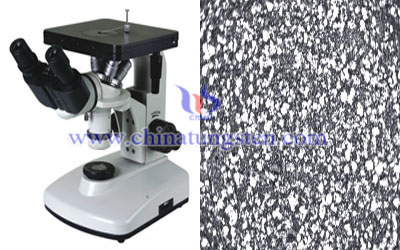

The metallographic testing steps of tungsten points:

1. Sample

Select the tungsten points’ material required for metallographic testing to determine the location and cut mode.

It is necessary to take the properties and processing aspects of tungsten points’ material into account, and then select representative sampling.

2. Inlay

If points’ materials have irregular shape or too small size, insert or holders for easy operation are needed.

3. Coarse and finish grind

(1) Coarse grind

The objective: flat points sample and grind to a suitable shape approximately. It should be coarse grinded on the grinder kibble when general steel material are needed, a file is needed if it is only soft material.

(2) Finish grind

The objective: eliminating deep cracks of the points’ material left by coarse grind, and make it ready for polish. In general, material grind methods can be divided, manual grind and mechanical grind.

4. Polish

The objective: removing fine cracks left by finish grind and to make its surface as bright as a mirror without trace. Generally polish is divided, electrolytic polish, chemical polish and mechanical polish, and mechanical polish is the most commonly used.

5. Corrosion

Corrosion process of points’ material is needed to polish points, so it is observed under a microscope. Metallographic corrosion methods contain chemical corrosion, electrolysis corrosion and constant potential corrosion, and chemical corrosion is the most commonly used.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com