Tungsten Carbide Insets with PVD Coatings (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 14:15

Physical vapor deposition (PVD) coatings are normally about 2-4 microns thick with hardness and chemical stable properties.

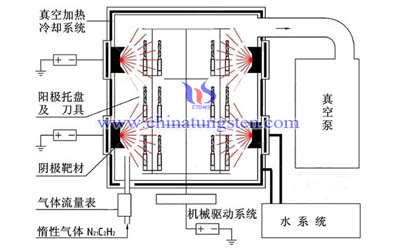

Generally the processes to help the tungsten carbide inserts to put on PVD coatings comprise, firstly the tungsten carbide inserts are required to be mounted on racks separately from each other. Besides setting the whole racks revolving within the vacuum furnace, each rack with the inserts is designed to expose every surface of the inserts is exposed to the deposition process. After that, a strong negative charge is applied to the inserts. Inside the vacuum furnace, there is a piece of titanium, or titanium and aluminum is installed on the wall or floor. The metal is vaporized by either an electric arc or an electron beam, liberating the positively charged metal ions. These ions are attracted to the negatively charged inserts. Nitrogen and methane are added as appropriate, to achieve the different types of coatings.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com