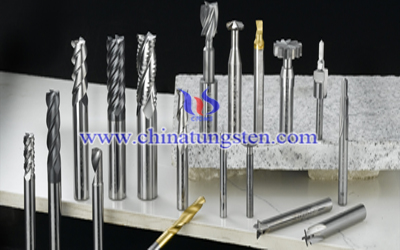

Tungsten Carbide Cutting Tools Coating Methods

- Details

- Category: Tungsten Information

- Published on Friday, 13 February 2015 09:35

High hardness of the coating layer or layers on the tungsten carbide cutting tools substrate coated tool wear good metal or non-metallic compound film, combined with the matrix of high strength, high toughness and coating of high hardness, high wear of advantage, reducing the friction factor between the cemented tungsten carbide cutting tools and the workpiece, to improve the wear resistance without lowering the toughness of the tool substrate. Therefore, coated tungsten carbide cutting tools with high hardness and excellent wear resistance, extend tool life, this is a revolution in the development of cutting tools.

Currently tungsten carbide cutting tools coating method is still a chemical vapor deposition (CVD) and physical vapor deposition (PVD) based, these two methods more prominent problem is the low bond strength between the coating and the substrate, coating easily peeled off, so that the coating can not be made too thick, and the coating once it is worn, the tool will wear rapidly. In recent years, there have been some new coating method appears as plasma-assisted chemical vapor deposition (PACVD), medium temperature chemical vapor deposition (MTCVD), sol - gel (Sol-Ge1), high-speed oxygen - Gas thermal spraying (HVOF ), vacuum cathodic arc deposition (VCAD) and other methods. The toughness of the cemented tungsten carbide cutting tools substrate by CVD, PVD, HVOF coating methods such as a thin layer of wear-resistant metal compound, allows the strength and toughness of the coating matrix to improve the abrasion resistance of the hard combining overall performance alloy tool.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com