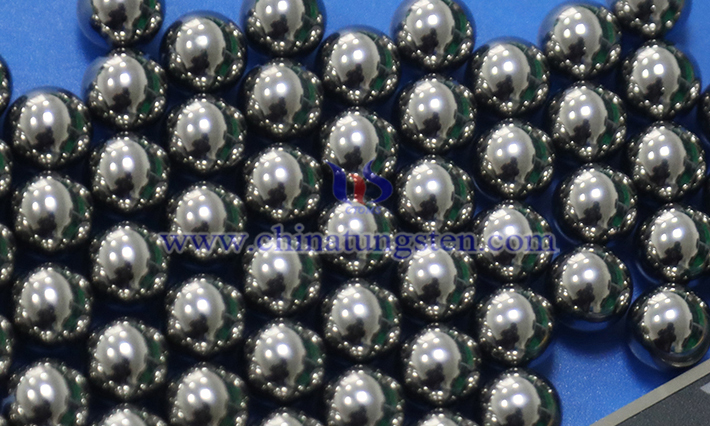

Tungsten Carbide Balls Manufacturing Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 17:45

The manufacturing process for tungsten carbide balls primarily includes the following steps, covering the entire process from raw material preparation to finished product inspection:

1. Raw Material Preparation:

Raw Material Selection: Select high-purity tungsten carbide (WC) powder, cobalt (Co) powder, or other metal binders (such as nickel and iron), as well as possible additives (such as titanium carbide and niobium carbide) to adjust properties.

Batching: Based on the performance requirements of the tungsten carbide ball (such as hardness and wear resistance), the powder raw materials are precisely weighed in a specific ratio.

2. Powder Mixing:

Place tungsten carbide, cobalt, and other powders in a ball mill. Add an appropriate amount of solvent (such as alcohol or water) and dispersant, and perform wet or dry grinding.

Ensure that the powder particles are evenly distributed and reach a micron-level particle size.

3. Drying and Granulation:

The mixed slurry is spray-dried to remove the solvent and form granules with good flowability for subsequent molding.

The granulation process can be completed using a spray dryer, resulting in granules of uniform size.

4. Molding:

Pressing: The granulated powder is loaded into a mold and pressed into spherical billets using cold isostatic pressing or die pressing techniques.

Preliminary Molding: The billets are initially processed into a nearly spherical shape through spheronization or rolling.

5. Pre-Sintering (Optional):

The pressed billets are pre-sintered at a relatively low temperature (approximately 800-1000°C) to remove additives (such as forming agents) and enhance their strength for subsequent processing.

6. Machining:

The billets are turned, ground, or spheronized to adjust their size and shape to a near-spherical final shape.

Specialized equipment (such as a ball mill or spheronizer) is used to ensure sphericity.

7. Sintering:

Vacuum Sintering or Hot Isostatic Pressing (HIP): The formed blank is placed in a vacuum furnace or hot isostatic pressing furnace and sintered at a high temperature of 1400-1500°C. This melts the cobalt phase and combines it with the tungsten carbide, forming a dense cemented carbide structure.

Sintering time typically ranges from 1-3 hours, depending on the size and composition of the ball.

Hot isostatic pressing can further increase the material density and performance.

8. Finishing:

Grinding and Polishing: The sintered tungsten carbide balls are precision ground using a diamond grinding wheel or polishing equipment to ensure a smooth surface finish and high sphericity.

Size Sorting: Precision screening or measuring equipment is used to ensure that the ball diameter tolerances meet the requirements.

9. Cleaning and Surface Treatment:

The tungsten carbide balls are ultrasonically cleaned to remove surface residues.

If required, surface coatings (such as PVD or CVD coatings) can be applied to improve wear or corrosion resistance.

10. Quality Inspection:

Dimensional and Geometric Tolerances: High-precision measuring instruments (such as roundness gauges and coordinate measuring machines) are used to inspect the ball's diameter, roundness, surface roughness, and other properties.

Performance Testing: Physical properties such as hardness, density, and compressive strength are tested.

Microstructural Analysis: Internal grain structure is examined using a metallographic microscope to ensure the absence of pores or cracks.

11. Packaging and Storage:

Qualified tungsten carbide balls are sorted by specification and packaged in shock- and moisture-proof packaging.

Store in a dry, constant-temperature environment to avoid oxidation and mechanical damage.

- Chinatungsten Online: tungsten-carbide.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com