Materials and Properties of Tungsten Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 17:29

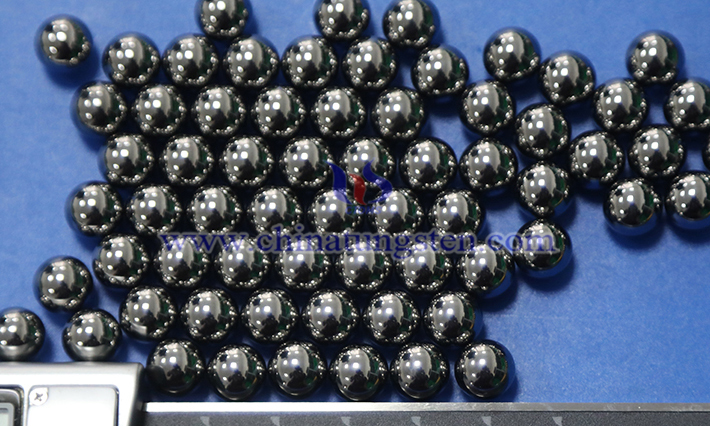

Tungsten cemented carbide balls are primarily made of tungsten carbide (WC) and a binder (such as cobalt (Co) or nickel (Ni)) through a powder metallurgy process. They exhibit high hardness, high wear resistance, corrosion resistance, and good compressive strength. The following is a detailed analysis of their materials and properties:

I. Material Composition

1. Main Components:

Tungsten carbide (WC): The core component of tungsten cemented carbide balls, with extremely high hardness (close to diamond, HRA 85-92), providing excellent wear resistance and compressive strength.

Binder: Typically cobalt (Co, typically 6%-12%) or nickel (Ni), it binds the tungsten carbide particles together, enhancing toughness and impact resistance. Cobalt improves strength, while nickel enhances corrosion resistance.

Other Additives: Small amounts of titanium carbide (TiC), tantalum carbide (TaC), or niobium carbide (NbC) are sometimes added to optimize specific properties, such as high-temperature hardness or oxidation resistance.

2. Material Characteristics:

High Hardness: Tungsten cemented carbide balls are significantly harder than ordinary steel, making them suitable for high-wear environments.

Customizability: By adjusting the binder content or additives, hardness, toughness, and corrosion resistance can be adjusted to meet different application requirements.

II. Performance Analysis

1. Hardness and Wear Resistance:

Tungsten cemented carbide balls typically have a Vickers hardness (HV) between 1400 and 1800, offering excellent wear resistance and suitable for high-precision grinding, bearings, valves, and other applications.

Wear resistance increases with decreasing WC particle size, and fine-grained carbide (e.g., submicron-grade) is more suitable for high-precision applications.

2. Compressive Strength:

With a compressive strength of 4000-6000 MPa, they can withstand high loads and are widely used in stamping dies, oil drilling tools, and other applications.

3. Toughness:

A higher binder content improves toughness, but with a slight decrease in hardness. Tungsten cemented carbide balls with a cobalt content of 6%-8% achieve a balance between hardness and toughness and are commonly used in general-purpose applications.

4. Corrosion Resistance:

Cobalt-based carbide has poor corrosion resistance in acidic environments, while nickel-based carbide is more suitable for chemically corrosive environments.

It has excellent high-temperature resistance and can maintain high hardness at 600-800°C.

5. Coefficient of Thermal Expansion:

It has a low coefficient of thermal expansion (approximately 4.5-6.0 × 10⁻⁶/K), good dimensional stability, and is suitable for precision machining.

- Chinatungsten Online: tungsten-carbide.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com