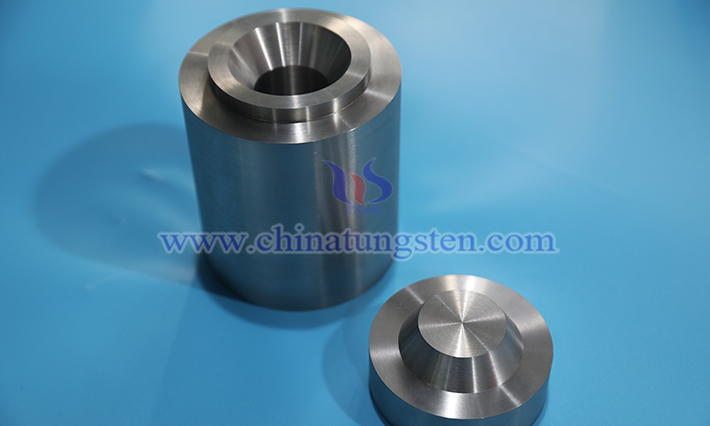

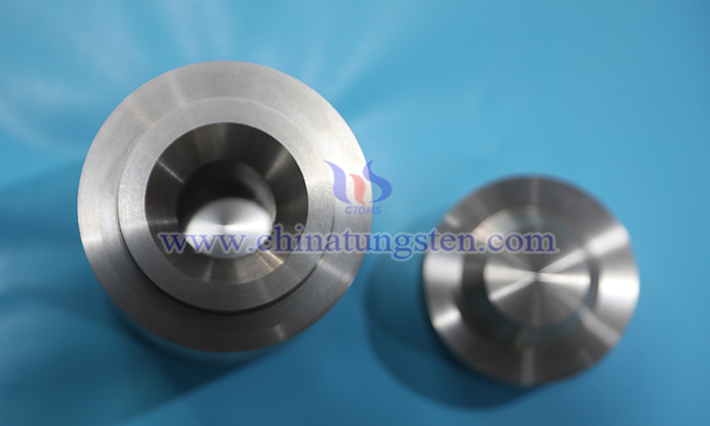

Tungsten Alloy Shielding Component

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 September 2025 14:10

Compared to traditional shielding materials such as iron, lead, and cement, tungsten alloy shielding components offer superior overall performance. For instance, under the same thickness and working conditions, tungsten alloy shielding materials provide better or longer-lasting shielding effectiveness and service life than traditional materials. Moreover, it is a non-toxic, environmentally friendly, and non-radioactive material, thus posing no secondary harm to the ecosystem. Below is an introduction to the basic information about these alloy shielding components.

1. Definition

It is both an alloy plate or cast alloy made with transition metal tungsten as the base and other metals like cobalt and nickel as auxiliary materials, and a device used to shield radioactive substances to prevent harm to human health or accelerate the aging rate of chemical materials.

2. Properties

It features a series of excellent characteristics, including high density, high strength, high hardness, wear resistance, heat resistance, corrosion resistance, oxidation resistance, non-toxicity, and non-radioactivity. Its strong radiation resistance is primarily due to its high density. However, the high hardness also makes mechanical processing extremely challenging.

3. Classification

Based on shape, it can be pided into shielding plates, protective casts, and similar forms.

Based on the type of radiation blocked, it can be categorized into X-ray shielding materials, gamma-ray shielding materials, and proton shielding materials.

Based on application fields, it can be classified into medical shielding components, industrial shielding components, and nuclear shielding components.

4. Manufacturing Process

Pour tungsten powder, nickel powder, copper powder, samarium powder, neodymium powder, silver powder, yttrium oxide, and tin oxide into a container, then place it in a vacuum heating furnace for drying to prepare the powder.

Transfer the powder from step 1) into a ball mill mixer for mixing to obtain a mixed powder, which is evenly pided into portions A, B, and C.

Weave molybdenum wire and rhenium wire into molybdenum wire mesh and rhenium wire mesh, respectively, and set aside.

Pour portion A of the mixed powder from step 2) into a mold, level it, then lay the molybdenum wire mesh on top. Next, pour portion B of the mixed powder into the mold, level it, and lay the rhenium wire mesh on top. Finally, pour portion C of the mixed powder, level it, and perform pressing to form the green compact, followed by demolding.

Place the green compact in a sintering furnace for pressure sintering, cool it to obtain a sintered body.

Place the sintered body in a vacuum furnace for vacuum heat treatment, then transfer the product to a heating furnace with argon protection for holding, followed by water quenching. Repeat this process four times to produce the shielding component.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com