Tungsten Wire Manufacturing Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 16:30

Tungsten Wire Manufacturing Process:

1. Raw Material Preparation (Tungsten Powder Preparation)

Tungsten Ore Extraction: Tungsten trioxide (WO₃) or tungstate is extracted from tungsten ore (such as wolframite or scheelite).

Chemical Reduction: Tungsten trioxide is reduced with hydrogen to produce high-purity tungsten powder. The reduction process is typically performed at high temperatures, resulting in tungsten powder with uniform particle size.

2. Doping (Optional)

To improve the properties of tungsten wire (such as its resistance to high-temperature deformation), trace amounts of dopants (such as potassium, aluminum, or silicon compounds) can be added to the tungsten powder to create doped tungsten powder. This doping process is often used to manufacture high-temperature-resistant tungsten wires.

Tungsten wires for different applications (such as incandescent lamps, vacuum tubes, and X-ray tubes) may require different doping or drawing processes.

3. Pressing

Tungsten powder is placed into a mold and pressed under high pressure (usually using a hydraulic press) into a tungsten bar (billet).

During the pressing process, pressure and powder uniformity must be controlled to ensure the density and strength of the billet.

4. Pre-sintering

The pressed tungsten bar is pre-sintered at a relatively low temperature (approximately 1000-1300°C) to enhance the mechanical strength of the billet and facilitate subsequent processing.

5. Sintering

In a high-temperature sintering furnace (approximately 2500-3000°C), the tungsten bar is heated to a temperature close to its melting point by direct or indirect heating. This allows the particles to fuse together to form a dense tungsten billet.

Sintering is typically performed in a hydrogen or vacuum environment to prevent oxidation.

6. Forging and Swaging

The sintered tungsten billet is then subjected to high-temperature forging or swaging to gradually reduce its diameter and increase its density and strength.

This step, through repeated heating and machining, forms the tungsten billet into a slender tungsten rod.

7. Wire Drawing

Tungsten rods are drawn through a series of drawing dies into progressively finer tungsten wires.

The wire drawing process requires high temperatures (approximately 1000-1500°C) to maintain the tungsten's ductility.

Lubricants (such as graphite emulsion) are used to reduce friction, and the diameter is gradually reduced through multiple drawing passes until the desired gauge (down to a few microns) is reached.

8. Annealing

During the drawing process, internal stresses are generated in the tungsten wire. Annealing (heating in hydrogen or a vacuum environment) is required to relieve these stresses and improve ductility and structural stability.

Annealing temperature and time vary depending on the diameter and intended use of the tungsten wire.

9. Cleaning and Surface Treatment

After drawing, the tungsten wire is cleaned to remove any residual lubricant or oxides on the surface.

Depending on the intended use, polishing or coating may be applied to enhance surface quality or specific properties.

10. Cutting and Forming

The tungsten wire is cut to desired lengths or wound into specific shapes (such as a spiral for a lamp filament). This step requires high-precision equipment to ensure dimensional consistency.

11. Quality Inspection

Finished tungsten wire undergoes multiple tests, including diameter, surface quality, mechanical properties (such as tensile strength), and resistivity.

For specialized applications (such as incandescent lamps or electronic devices), high-temperature performance and lifespan testing are also required.

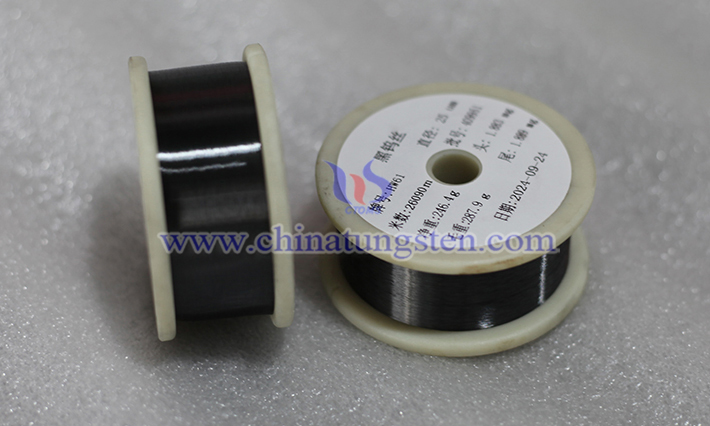

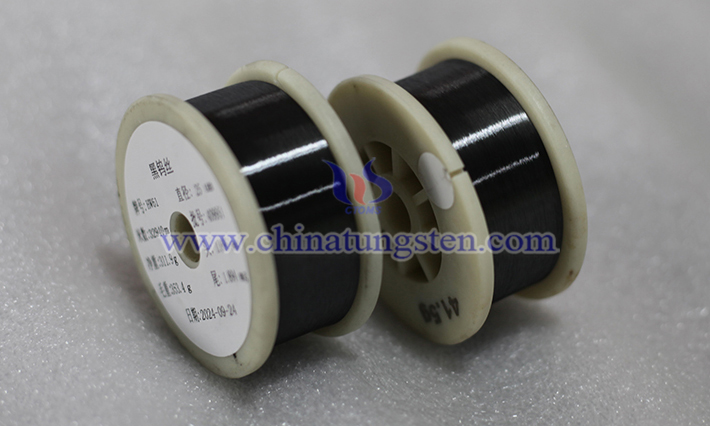

12. Packaging and Storage

Qualified tungsten wire is coiled and packaged according to specifications and stored in a dry, oxygen-free environment to prevent oxidation.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com