Working Principle of Barium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 10 April 2025 20:15

The barium tungsten electrode is a highly efficient thermionic electron emission cathode. Its working principle is based on the reduction of the work function of the tungsten substrate surface by the active substance of barium, thereby significantly improving the electron emission efficiency. The following is a detailed analysis of its working principle:

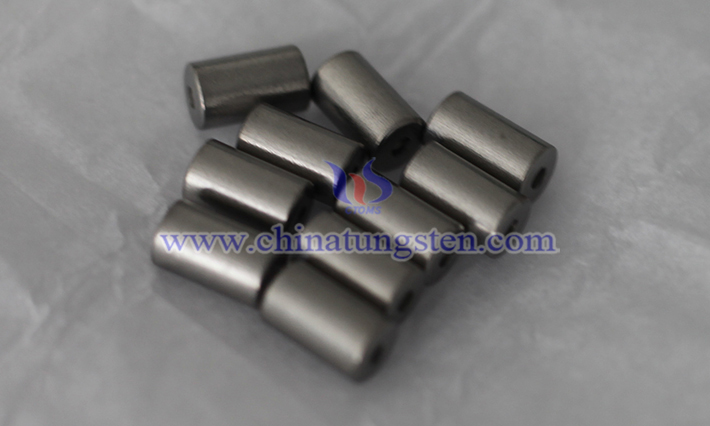

1. Basic Structure and Materials of Barium Tungsten Electrode

Tungsten substrate: As the main material of the electrode, tungsten can maintain structural integrity at high temperatures due to its high melting point (about 3422°C) and excellent thermal stability.

Barium active substance: Usually impregnated in the pores of the tungsten substrate in the form of barium aluminate (such as BaO·Al₂O₃) or barium oxide, the barium atoms are released by high temperature activation.

2. Electron Emission Mechanism of Barium Tungsten Electrode

Work function reduction: The work function of pure tungsten is relatively high (about 4.5 eV), while barium atoms form an adsorption layer on the tungsten surface. Its low ionization energy (about 2.7 eV) leads to a surface dipole effect, which significantly reduces the effective work function (can be reduced to about 2.0 eV).

Enhanced thermal electron emission: According to the Richardson-Dushman equation, reducing the work function can significantly increase the emission current density at the same temperature, or maintain high emission efficiency at a lower temperature.

3. Supply and Diffusion of Barium

Impregnation process: The barium compound is impregnated into the porous tungsten matrix and decomposes when heated (such as BaO is reduced by tungsten at high temperature), generating free barium and diffusing along the pores to the surface.

Dynamic balance: The surface barium atoms are gradually lost due to evaporation or ion bombardment, but are continuously replenished inside the matrix to ensure long-term stable emission. The working temperature needs to be optimized to balance the evaporation rate and diffusion rate.

4. Chemical and thermodynamic Processes of Barium Tungsten Electrodes

Activation reaction: When heated at high temperature for the first time, the barium compound undergoes a reduction reaction (such as 6BaO + W → 3Ba + Ba₃WO₆), releasing metallic barium.

Surface renewal: The migration ability of barium is enhanced at high temperature, and the surface covering layer is repaired in time to maintain a low work function state.

5. Performance Advantages and Applications

High emission efficiency: suitable for high current density demand scenarios, such as microwave tubes, traveling wave tubes, X-ray tubes, etc.

Long life and stability: The high temperature resistance of tungsten combined with the continuous supply of barium prolongs the service life of the device.

Environmentally friendly alternative: Compared with radioactive thorium tungsten cathodes, barium tungsten is safer and suitable for fields with strict environmental protection requirements.

6. Key Design Considerations of Barium Tungsten Electrodes

Pore structure: The porosity of the porous tungsten matrix directly affects the storage and diffusion efficiency of barium.

Temperature control: The operating temperature needs to be precisely controlled to prevent barium from evaporating too quickly or diffusing insufficiently.

Material compatibility: Avoid adverse reactions between barium and surrounding materials to ensure the overall stability of the device.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com