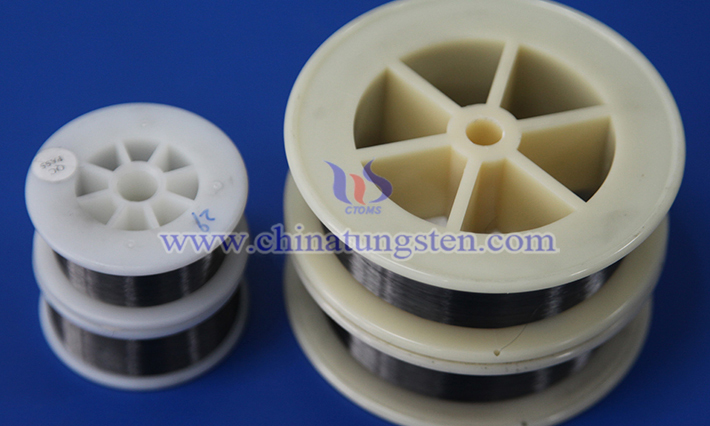

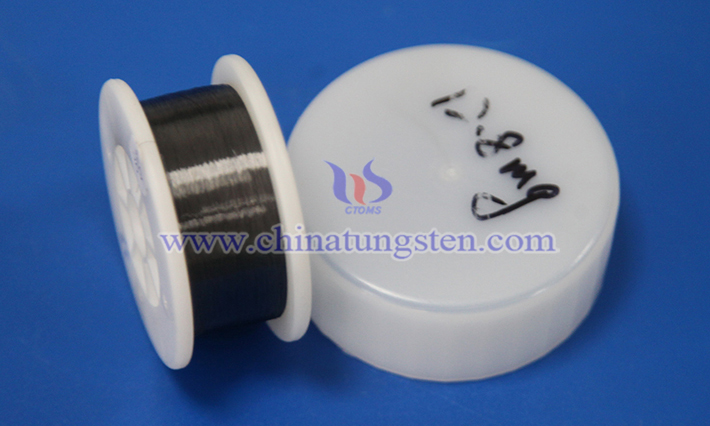

Performance of Cut-Resistant Tungsten Wire in High-Temperature Environments

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 April 2025 19:41

The performance of cut-resistant tungsten wire in high-temperature environments is significantly superior to many other metallic materials, primarily due to tungsten's inherent properties. Below is a detailed analysis of its high-temperature characteristics:

1. High Melting Point and Thermal Stability

Extremely high melting point: Tungsten has a melting point of 3422°C (one of the highest among all metals), allowing it to remain solid under extreme heat without softening or melting.

High-temperature strength: Even above 1000°C, cut-resistant tungsten wire retains high tensile strength and hardness, whereas ordinary steel or nickel-based alloys may soften significantly at such temperatures.

2. Oxidation Resistance and Corrosion Resistance

Poor oxidation resistance at room temperature: Tungsten is sensitive to oxidation in ambient conditions, forming brittle oxides (WO₃) on its surface, which may degrade performance.

Need for high-temperature protection: In oxygen-rich high-temperature environments (e.g., above 500°C), protective measures such as surface coatings (e.g., silicides, noble metals) or inert gas/vacuum environments are required to prevent oxidation.

Advantage in inert environments: In vacuum or inert atmospheres (e.g., argon), the high-temperature performance of cut-resistant tungsten wire remains largely unaffected, making it suitable for applications like high-temperature furnaces and semiconductor equipment.

3. Creep Resistance

Low creep rate: Tungsten exhibits minimal creep deformation under prolonged stress at high temperatures, making it ideal for long-term stability applications (e.g., high-temperature springs, support structures).

4. Thermal Expansion and Conductivity

Low thermal expansion coefficient: Tungsten’s thermal expansion coefficient (4.5×10⁻⁶/°C) is close to that of ceramics, ensuring excellent dimensional stability under thermal cycling and reducing stress-induced cracking.

High thermal conductivity: Its good thermal conductivity (173 W/m·K) facilitates rapid heat dissipation, preventing localized overheating.

5. Applications and Limitations

Typical applications:

Heating elements in high-temperature furnaces (requires protective atmosphere).

Cutting tools (e.g., laser cutting nozzles, high-temperature wire saws).

Aerospace components (e.g., high-temperature sensors).

Limitations:

Low-temperature brittleness: Tungsten is brittle at low or room temperatures, making it difficult to machine.

Higher cost: Pure tungsten and its alloys are more expensive to produce than common metals.

6. Improvement Strategies

Alloying: Adding rhenium (Re) enhances high-temperature ductility (e.g., W-25Re alloy).

Coating technology: Anti-oxidation coatings (e.g., HfC, SiC) can extend service life in oxygen-rich environments.

Composite materials: Combining with ceramic fibers can further improve thermal shock resistance.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com