Advantages of Cut-Resistant Tungsten Wire Protective Gloves

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 April 2025 19:19

Cut-resistant tungsten wire protective gloves are a kind of hand protection equipment that combines high-strength materials and advanced textile technology. They are widely used in high-risk fields such as industry, manufacturing, and construction. Its core advantages are mainly reflected in the following aspects:

1. Ultra-High Cut Resistance

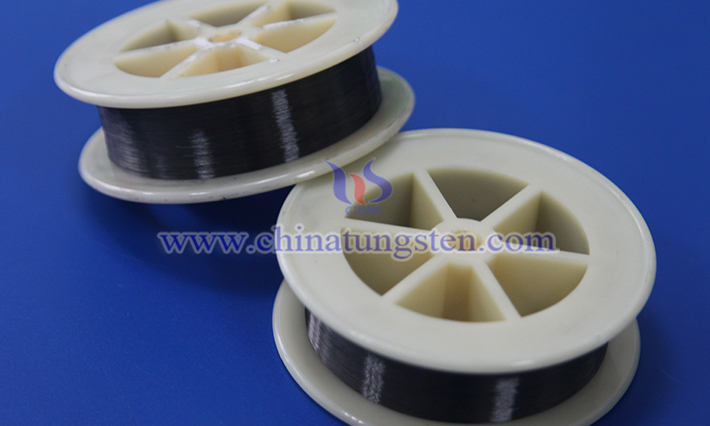

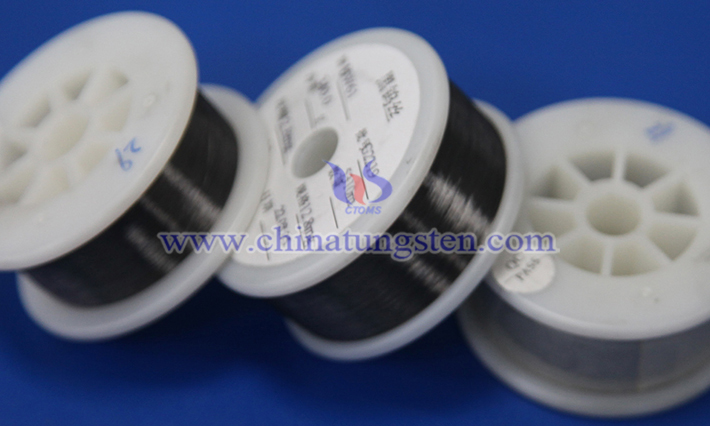

Tungsten wire material characteristics: Cut-resistant tungsten wire is a high-hardness, high-wear-resistant metal fiber with a strength far exceeding that of ordinary steel wire. By composite weaving with other high-performance fibers (such as HPPE and aramid), the cut resistance of gloves is significantly improved.

High protection level: usually reaches level 5 or higher (up to level 6) in the EN388 standard, which can resist the risk of cutting by sharp objects such as sharp metals, glass, knives, etc., and is suitable for high-risk operation scenarios.

2. Flexibility and Comfort

Ultrafine fiber weaving: The diameter of the tungsten wire is extremely fine (usually micrometer level). After weaving, the gloves remain soft and fit the hands, without affecting the flexibility of the fingers and the grip accuracy, and are suitable for delicate operations.

Breathable design: Some products use breathable lining (such as spandex, cotton) or honeycomb structure to reduce the feeling of stuffiness in the hands and are suitable for long-term wear.

3. Lightweight and Durability

Realization of lightweight: Although tungsten itself has a high density, due to its ultra-high strength (tensile strength far exceeds that of steel wire), in actual applications, extremely fine tungsten wire (micrometer level) can be used for weaving to reduce the amount of material used, so that the overall weight of the gloves is still about 30%~50% lighter than traditional steel wire gloves, while maintaining high protective performance.

Abrasion resistance and corrosion resistance: Tungsten wire is resistant to oxidation and corrosion, and the fiber structure is stable. It is not easy to break or deform after long-term use, and has a longer life.

4. Multifunctional Protection

Composite protection design: Some products integrate functions such as anti-puncture, anti-friction (EN388 Abrasion), and anti-static (EN1149) to meet the needs of multiple scenarios (such as electronic manufacturing and automobile assembly).

Tactile optimization: The sensitivity of the palm is maintained through special processes, which is suitable for jobs that require the operation of precision tools or parts.

5. Wide Application Scenarios

Industrial manufacturing: automotive parts processing, metal stamping, glass processing, etc.

Logistics and warehousing: Prevent cuts when sorting sharp objects (such as knives and metal sheets).

Food processing: Deal with high-cutting risk links such as meat cutting and seafood processing.

Emergency rescue: Prevent glass fragments or sharp objects from being injured during firefighting and rescue.

6. Economical

Low long-term cost: Although the unit price of cut-resistant tungsten wire is higher than that of ordinary gloves, its ultra-long service life can reduce the frequency of replacement and the overall cost is lower.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com