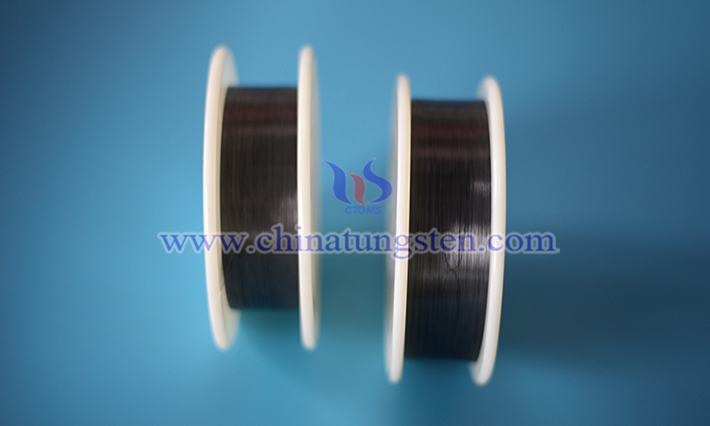

Manufacturing Process of Cut-resistant Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 March 2025 19:41

Below is a detailed introduction to the manufacturing process of cut-resistant tungsten wire, covering the entire procedure from raw material selection to final product inspection.

1. Raw Material Preparation

Tungsten Powder Purification: Utilizing hydrogen reduction or chemical vapor deposition (CVD) to prepare high-purity tungsten powder (purity >99.95%), with controlled impurity levels of oxygen, carbon, etc.

Doping and Modification: Adding trace alloy elements (such as rhenium, lanthanum oxide, thorium oxide) to improve ductility and high-temperature resistance.

2. Powder Metallurgy Forming

Isostatic Pressing: Loading tungsten powder into molds and pressing into rod blanks through cold isostatic pressing (CIP) or hot isostatic pressing (HIP), achieving a density of 60%~80% of theoretical density.

Pre-sintering: Pre-sintering at low temperatures (1200~1500°C) in a hydrogen atmosphere to initially form a porous structure.

3. High-temperature Sintering

Vertical Sintering: Using a vertical sintering furnace under hydrogen protection at high temperatures (2200~2800°C) to densify the blanks (density >95%) and eliminate internal pores.

Spark Plasma Sintering (SPS): A rapid sintering technique that reduces the risk of grain coarsening and enhances material uniformity.

4. Thermo-mechanical Processing (Wire Drawing)

Hot Rolling and Swaging: Heating the sintered blanks to 1400~1600°C (above the recrystallization temperature) and gradually reducing the diameter to several millimeters through rolling or swaging.

Multi-pass Wire Drawing: Using diamond dies for cold or hot drawing, with a reduction rate of 5%20% per pass, accompanied by intermediate annealing (10001200°C) to eliminate work hardening.

Ultra-fine Wire Control: When the diameter is <0.01mm, using electrolytic polishing or ultrasonic-assisted wire drawing to prevent breakage.

5. Surface Treatment and Coating

Chemical Cleaning: Acid pickling (e.g., a mixture of nitric acid and hydrofluoric acid) to remove surface oxides and impurities.

Coating Techniques: CVD/PVD coating involves depositing tungsten carbide (WC), titanium nitride (TiN), etc., through chemical/physical vapor deposition to enhance surface hardness and wear resistance; electroplating with nickel or chromium to enhance corrosion resistance.

6. Doping and Alloying Processes

Rhenium Doping: Adding 1%~5% rhenium (Re) significantly improves ductility and fatigue resistance.

Rare Earth Oxide Reinforcement: Incorporating lanthanum oxide (La₂O₃) to refine grains and inhibit high-temperature grain growth.

7. Post-processing and Finishing

Heat Treatment: Annealing (to relieve stresses) or aging treatment (for alloy wires) to optimize mechanical properties.

Straightening and Cutting: Using laser straightening to ensure straightness and precision cutting to the target length.

8. Quality Control and Inspection

Defect Detection: X-ray flaw detection and ultrasonic testing to identify internal cracks or pores.

Performance Testing: Tensile strength (ASTM E8), hardness (ASTM E384); high-temperature cycling tests (simulating actual working conditions).

9. Optimization of Special Processes

Nanostructured Tungsten Wire: Prepared through sintering of nano-powders or electrodeposition to enhance strength and toughness.

Composite Coating Multi-layer Design: Alternately depositing hard coatings and buffer layers (e.g., WC+TiAlN) to balance wear resistance and impact resistance.

10. Key Process Parameters

Wire Drawing Temperature: Cold drawing (room temperature) or hot drawing (800~1200°C).

Die Material: Diamond (for ultra-fine wires) or carbide (for coarse wires).

Annealing Cycle: Annealing for 1~2 hours after each wire drawing pass.

Through these processes, cut-resistant tungsten wire achieves comprehensive properties of high hardness, high strength, and resistance to extreme environments, meeting the demanding requirements of industrial cutting, high-temperature equipment, and other applications.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com