Applications of 3D Printing Technique in Aviation Industry

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2013 09:45

Put powder raw materials into printer and then you can produce whatever you need such as toys, models, faking artifact, automobile components and even human organs by the influences of laser. The technique is called as 3D printing technique which is popular around the wo rld and being consider as “ improving the realization of the third Industrial Revolution” by The British Economist.

rld and being consider as “ improving the realization of the third Industrial Revolution” by The British Economist.

Generally, people always consider that the U.S. is leading the industrial revolution. However, some news coming from China is shocking.

Those news shows that China has become the only nation which has hold lasing forming manufacturing technique of main bearing refractory metal parts and put the technique into application. By using 3D printing technique of refractory metal aircraft parts, it is the first time that China becomes the forefront of advanced level around the world in aerial materials industry.

Contributors for blowout of Chinese advanced fighters

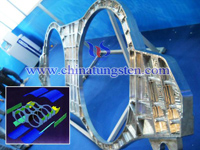

Recently, in China Beijing international high-tech Expo, AVIC (Aviation Industry Corporation of China) and Beijing University of Aeronautics & Astronautics shows the whole aircraft key refractory metal aircraft parts which are being manufactured by 3D printing technique and rewarded for the first prize of State Technological Invention Award, and a 5m2 strengthen frame.

The foreign medium report that 3D printing technique is being widely used for the development of J-15 the first Chinese carrier aircraft, J-16 multirole combat aircraft, J-20 the fifth generation heavy fighters, J-31 the fifth generation medium fighters and C919 civil aircraft.

News Channel of CCTV reports that the main bearing refractory metal aircraft parts, being manufactured by 3D  printing technique have been widely used for J-15, including the whole former landing chassis.

printing technique have been widely used for J-15, including the whole former landing chassis.

The application of 3D printing technique speeds up the development of Chinese advanced fighters. Relying on low cost and high speed of laser refractory metal aircraft parts forming technique, Shenyang Aircraft Corporation can assemble J-15, J-16, J-31 and other fighters and test flight in a year.

By adopting 3D printing technique, refractory metal aircraft parts which have complicated or special structure can take shape once without forging one by one and welding together, high improving the strength of fuselage.

According to the estimate, if refractory metal aircraft parts in F-22 are manufactured by Chinese 3D printing technique, the weight will decrease by 40% under the same strength. That will highly improve the thrust weight ratio and the properties of fighters.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com