3D Printing Technology & Refractory Metal Material

- Details

- Category: Tungsten Information

- Published on Thursday, 30 May 2013 18:31

Refractory metal is generally a kind of metal whose melting point is higher than 1650℃ and has definite reserves. The metals whose melting point is higher than Zr (1852℃) are also called as refractory metal. Refractory metal material is a kind of alloys which is based on refractory metal as matrix and add s with other metal elements. 3D printing technology is a kind of techniques which is based on files of mathematical model, utilizing refractory metal material and manufacturing substance by printing layer by layer. 3D printer appeared at the mid-term of 1990’s. It is a kind of rapid prototyping devices by using light-cure and paper stacking up. The operational principle is similar to general printer. There is refractory metal powder in 3D printer. When connecting with computer, the printer superimposes refractory metal material layer by layer, being controlled by computer. Lastly, the blueprint in computer will be change into material object. At present, 3D printing technology has been widely adopted in aviation industry for manufacturing main bearing components of fighter. The most outstanding advantage of 3D printing technology is that graphic data of computer can produce any shapes components directly, without machine work or moulds, so that can reduce lead time of product, improve productivity and lower cost.

s with other metal elements. 3D printing technology is a kind of techniques which is based on files of mathematical model, utilizing refractory metal material and manufacturing substance by printing layer by layer. 3D printer appeared at the mid-term of 1990’s. It is a kind of rapid prototyping devices by using light-cure and paper stacking up. The operational principle is similar to general printer. There is refractory metal powder in 3D printer. When connecting with computer, the printer superimposes refractory metal material layer by layer, being controlled by computer. Lastly, the blueprint in computer will be change into material object. At present, 3D printing technology has been widely adopted in aviation industry for manufacturing main bearing components of fighter. The most outstanding advantage of 3D printing technology is that graphic data of computer can produce any shapes components directly, without machine work or moulds, so that can reduce lead time of product, improve productivity and lower cost.

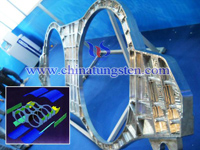

3D printing technology can not only be used for manufacturing plastic gun. At present, 3D printing technology has been widely used in developing and manufacturing of weapons around the world. Advanced 3D printing  technology can not only sinter or fuse plastic, wax and sand, it can also sinter refractory metal directly. In traditional manufacturing process of fighter, it needs long-term investment for manufacturing hydraulic forming equipment after finishing design of fighter 3D model. The processes of shaping and application of components have been improved largely while using 3D printing technology. The main bearing components, being made by refractory metal material and manufactured by 3D printing technology has been widely used for J-15, the first Chinese carrier aircraft, including the whole former landing chassis. It is said that the refractory metal material which is manufactured by 3D printing technology will be also used for J-20 and J-31, the fifth generation fighter.

technology can not only sinter or fuse plastic, wax and sand, it can also sinter refractory metal directly. In traditional manufacturing process of fighter, it needs long-term investment for manufacturing hydraulic forming equipment after finishing design of fighter 3D model. The processes of shaping and application of components have been improved largely while using 3D printing technology. The main bearing components, being made by refractory metal material and manufactured by 3D printing technology has been widely used for J-15, the first Chinese carrier aircraft, including the whole former landing chassis. It is said that the refractory metal material which is manufactured by 3D printing technology will be also used for J-20 and J-31, the fifth generation fighter.

3D printing technology can be also used for maintenance and guarantee of weapons in the battlefield directly. At present, the U.S. army has already deployed mobile laboratory in Afghanistan. The U.S. Army is also speeding up the combat deployment of 3D printing technology, so that can improve the maintenance ability of weapons and enhance persistent combat effectiveness during wartime. The damaged components can be printed by using 3D printing technology timely and assembled by maintenance personnel so that weapons can join in battle again.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com