Researchers Create New Tungsten Substitute Catalyst for Vanadium Oxide

- Details

- Category: Tungsten Information

- Published on Thursday, 31 March 2022 17:41

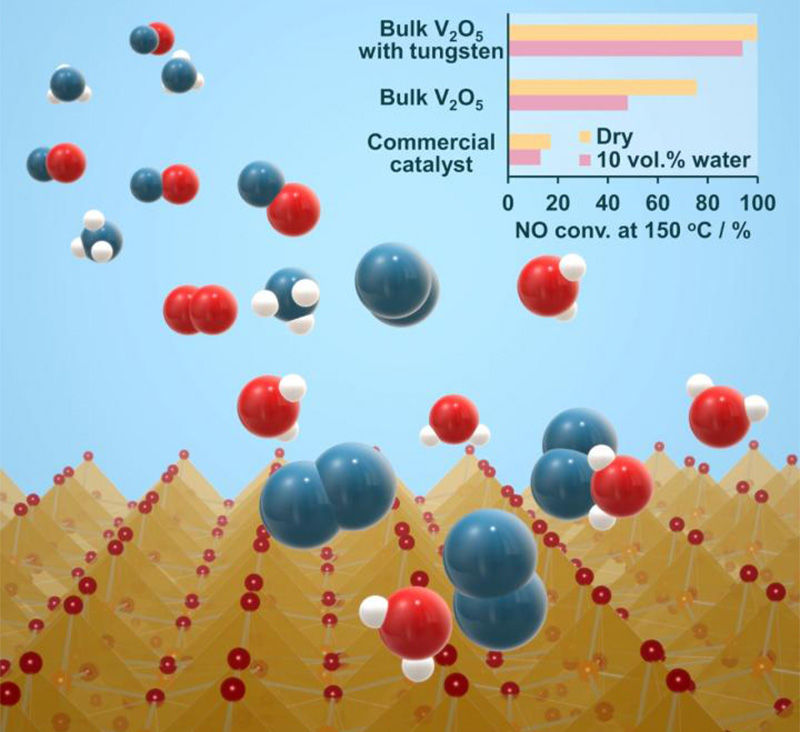

Researchers from Tokyo Metropolitan University have created a new tungsten (W) substituted vanadium oxide catalyst for breaking down harmful nitrogen oxides in industrial exhaust gases. Their new material is able to operate at lower temperatures and does not exhibit a significant degradation in performance when treating "wet" exhaust gases, addressing a major drawback of conventional vanadium oxide catalysts. The researchers also found that the non-aggregated dispersion of atomic tungsten in the original crystal structure plays a key role in its function.

The study titled “Bulk tungsten-substituted vanadium oxide for low-temperature NOx removal in the presence of water” has been published in the journal Nature Communications (2021). The study was carried out by Yusuke Inomata et al.

Credit: Tokyo Metropolitan University

Selective catalytic reduction (SCR) is an important technology for keeping the air clean. Industrial exhaust gases pass through a catalytic device and react with a reducing agent to convert harmful nitrogen oxides into nitrogen gas and water. High levels of nitrogen oxides not only harm crops and vegetation but can also directly harm humans by exacerbating asthma and other respiratory problems. This makes the widespread and efficient deployment of selective catalytic reduction technologies particularly important to society.

In previous work, a team led by Professor Toru Murayama of Tokyo Metropolitan University created a new vanadium-oxide catalyst that works effectively at 100 to 150 degrees Celsius. However, the lower temperatures led to another problem, namely water vapor. At lower temperatures, industrial off-gases typically contain 10-20% water vapor (by volume). Since the performance of vanadium-oxide catalysts can be severely degraded when the gas is wet, further breakthroughs are needed to take full advantage of this new catalytic material.

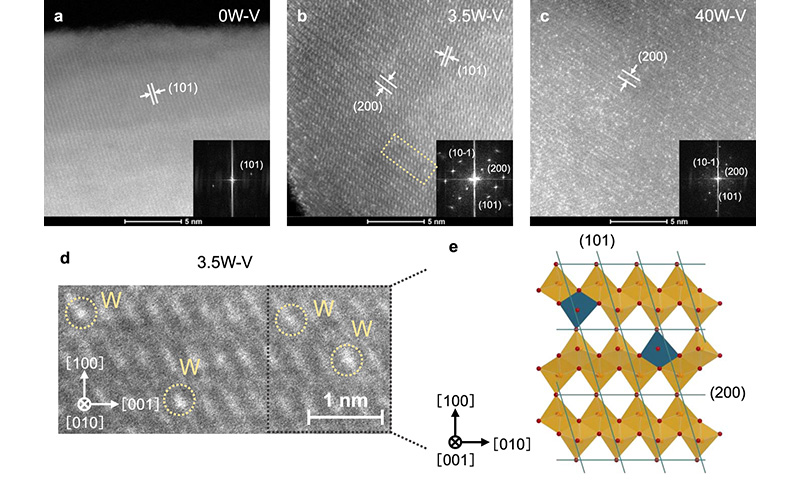

The team has now solved this problem by creating a new, tungsten-substituted vanadium oxide catalyst. By replacing some of the vanadium in the crystalline structure with W, they found that it was no longer susceptible to a significant drop in performance. This makes the material ideal for treating real industrial off-gases.

Credit: Tokyo Metropolitan University

However, more W does not necessarily mean better performance. The team found that the right amount of non-aggregating atomic dispersion of W is critical. Both tungsten and vanadium need to work together: under humid conditions, the W-substituted material provides more sites for the production of ammonium ions that can subsequently react with nitrogen oxides in the vicinity of neighboring vanadium ions. The team hopes that their insights into the mechanism and the superior performance of their catalyst under realistic conditions will lead to new industrial SCR products and cleaner air in the near future.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com