Synthesis of Tungsten Carbide by Electrical Explosion of Wire

- Details

- Category: Tungsten Information

- Published on Saturday, 26 March 2022 18:52

Recently, a research team from the Russian Academy of Sciences has successfully prepared tungsten carbide (WC) powder in this study by synthesizing bimodal tungsten powder by electrical explosion of wire (EEW) method and investigated the carburization process of EEW bimodal tungsten powder.

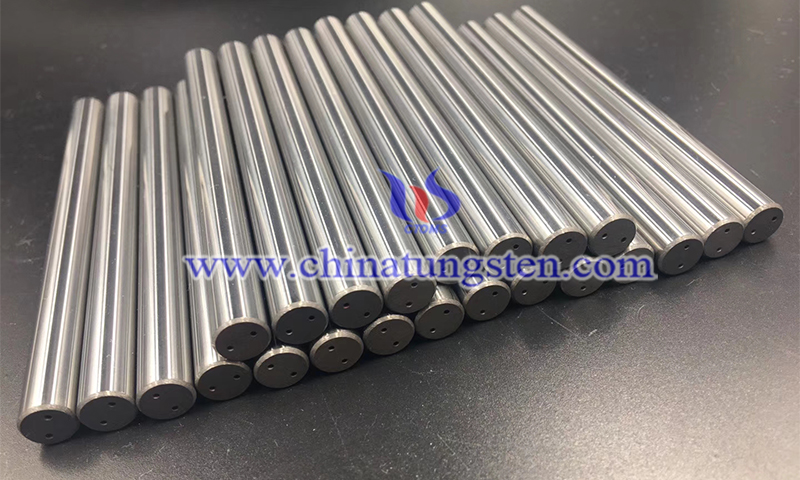

WC has been of great interest due to its unusual and unique physical and mechanical properties. WC is characterized by high melting point, high hardness, high fracture toughness, low coefficient of friction, high chemical inertness, high resistance to oxidation and corrosion, and good electrical conductivity. WC is used in industry for the production of cutting and stamping tools, mining tools, drilling tools, and wear-resistant applications, as well as heterogeneous oxide green catalysts, hydrogen evolution, and oxygen reduction reactions, electrocatalysis, fuel cells, and petroleum processing.

Today, powder injection molding (PIM) technology is commonly used to produce wear-resistant parts, tools, and non-ferrous alloys, and this technology requires highly dispersed WC powders.

There are many processes for synthesizing WC powders, but all have one thing in common: the formation of tungsten metal from a precursor followed by a carburization process. In many cases, WC powders are produced by direct carburization of tungsten powder mixed with carbon. This process is very time-consuming and usually requires high carburizing temperatures to be maintained for long periods.

The interaction of tungsten and carbon usually takes place in a solid-solid reaction, where the carbon diffuses into the metal particles, followed by a chemical reaction of reagents that can form tungsten semicarbazide W2C. Further carburization causes the transformation of W2C into WC.

The chemical reaction of nanoparticles proceeds at a higher rate and starts at a lower temperature compared to the reaction of micron-sized particles. The properties of tungsten nanoparticles allow the preparation of WC by direct carburization. Nanomaterials have many surface atoms, giving them high surface activity and exhibiting high reactivity.

In PIM technology, particle size influences the production process and the performance of the final part. The finer the powder used, the better the properties of the part. This is because the lower the surface roughness of the part and the reduced pore size will result in a higher density of the material.

However, the reduction in particle size can also lead to significant changes in the physical and mechanical properties of the powder. Nano-powders have low mobility and high oxidation activity; they exist as porous agglomerates that mix poorly with each other and with the microparticles. Relatively homogeneous mixtures can only be formed with degranulated particles of almost the same size.

A combination of microparticles and nanoparticles in a certain ratio (bimodal materials) is a more suitable material. In bimodal materials, the nanoparticles fill the voids between the submicron particles, resulting in a low porosity of the material. The use of bimodal compositions also improves the mechanical properties of the part, such as microhardness and tensile strength. Similarly, the use of compositions with WC bimodal powders produces similar effects.

Nowadays, bimodal powders are mainly obtained through powder blending and are currently not available for mass production for the time being. One of the effective methods for producing metal, alloy, and ceramic powders is electrical explosion of wire. This method is versatile, low waste, and environmentally friendly. the main advantage of EEW is the possibility of producing bimodal powders with low aggregation. Unlike micro/nano-powder mixtures, the resulting powders are homogeneous and do not segregate.

Recently, the team successfully prepared bimodal tungsten carbide powder by a two-stage process: EEW synthesis of bimodal tungsten powder followed by carburization reaction, and the carbon content in the obtained WC powder was very close to the theoretical value. Thus, the carburization process of bimodal tungsten powder may provide a low-cost and efficient way to prepare WC powders for various applications.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com