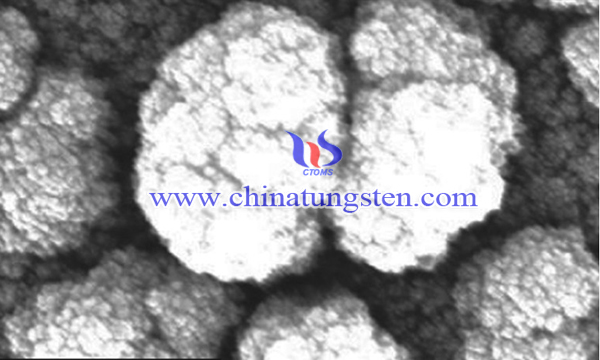

Synthesis of Nanosized Tungsten Trioxide Cauliflowers

- Details

- Category: Tungsten Information

- Published on Thursday, 04 November 2021 01:09

In recent years, photoelectrochemical (PEC) water splitting has attracted people's attention, and it is considered to have potential applications in solar energy conversion. The effectiveness of solar energy conversion mainly depends on the structure of the photoelectrode. In addition, nanostructured photoelectrodes and surface porosity have additional advantages in in improving the efficiency since they exhibit unique properties of light-harvesting, chemical stability, active surface area, and charge separation.

Nany researchers have been focused on the fabrication of high efficient nanostructured tungsten trioxide (WO3) photoanodes such as nanowires, nano-plates, nanoflakes, nanotubes, and nanorods. Therefore, it is reported that nanosized tungsten trioxide cauliflowers are fabricated onto silica glass by aerosol assisted chemical vapor deposition (AACVD) under the reaction of tungsten hexacarbonyl and multi walled carbon nanotubes (MWCNT) solutions in toluene. The preparation procedure is as below:

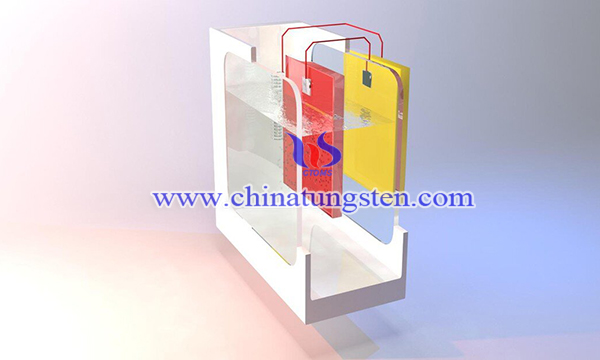

Aerosol assisted chemical vapor deposition (AACVD) of nanosized tungsten trioxide (WO3) cauliflowers was carried out in a reactor with a tubular horizontal bed cold wall of 17 cm×6 cm in size. Precursor solutions of tungsten hexacarbonyl (99%, Aldrich) and multi-walled carbon nanotubes (>95%, Aldrich) were prepared in toluene (>>99.6%, Sigma-Aldrich). A fixed concentration of 0.5 g tungsten hexacarbonyl was used and mixed with MWCNT(concentration of 0.25%) in 50 mL of toluene. Place the precursor mixture on a magnetic stirrer for at least 30 minutes to ensure uniform dissolution of the chemicals. In the presence of nitrogen (N2, 99.9%, BOC), an ultrasonic humidifier is used to generate a solution aerosol in the form of mist, which delivers the sol to the reactor at a flow rate of 1.5 L/min. All depositions were performed on quartz glass coated with a SiO2 layer (Pilkington NSG). Before deposition, the glass slide was cut into (90mm×45mm×4mm) size, and ultrasonically cleaned with acetone and deionized water for 10 minutes to remove surface contaminants. The temperature of all deposited substrates is maintained at 400°C, and the deposition time lasts for one and a half hours.

In summary, nanosized tungsten trioxide cauliflowers are fabricated onto silica glass by aerosol assisted chemical vapor deposition (AACVD) under the reaction of tungsten hexacarbonyl and MWCNT solutions in toluene. Optical transmittance was decreased with variation due to color fringes of films while absorbance was increased between 300nm. and 400 nm. This increase was due to trapping sites and defects generated in addition of multiwalled CNTs which also shifted the Fermi level and as a result band gap energy get increased up to 3.18 eV.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com