Tungsten Carbide Hollow Microsphere Prepared via Ammonium Metatungstate as Electrocatalyst Support

- Details

- Category: Tungsten Information

- Published on Monday, 13 September 2021 11:55

Hydrogen (H2) is widely concerned as the most potential candidate due to its high energy density and environmentally friendly reaction process. Electrochemical water splitting is a promising hydrogen production technology because it does not contain greenhouse gases and is economical and efficient. As a key semi-reaction process, the hydrogen evolution reaction (HER) plays a decisive role in the efficiency and cost of hydrogen production through electrochemical water splitting.

Tungsten carbide (WC) has been investigated extensively as low-cost HER catalysts on account of its robust electrochemical stability, superior electronic conductivity, and earth-abundant resources. Therefore, WC with a special hollow structure was successfully synthesized, and its HER ability as a bulk catalyst and Pt electrocatalyst support was studied. Ammonium metatungstate is used to prepare hollow tungsten carbide microspheres as the electrocatalyst support for the hydrogen evolution reaction. The experimental steps are as follows:

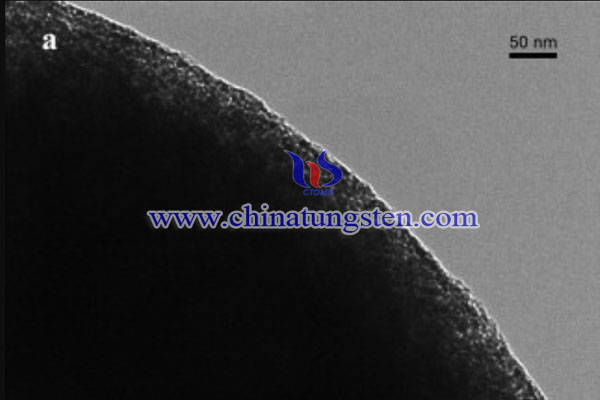

Dissolve the excess ammonium metatungstate (AMT) and glucose in 60 ml of deionized water and disperse it completely by ultrasonic vibration for half an hour. The transparent solution was then transferred to a sealed 100 ml stainless steel autoclave lined with PTFE and heated to 200 °C for 10 hours. After being naturally cooled to room temperature (25°C), the product was filtered, and then washed several times with deionized water and ethanol. Finally, the precipitate was collected and dried in a vacuum oven at 80°C for 8 hours to obtain a loose powder precursor. The precursors include tungsten-containing materials and carbonized polymers, which are spherical particles under a scanning electron microscope. The formation of this complex precursor can be attributed to the polycondensation process of glucose. When glucose molecules are dehydrated and carbonized into carbon spheres, their hydrophilic groups can be complexed with the amino or tungstic acid groups of AMT. Therefore, the tungsten species is fixed in the spherical particles, and the precursor of this spherical structure can form a special spherical shape in the later processing. In order to remove those unexpected elements and finally synthesize massive WC, the dispersed precursor is slowly heated to the set temperature at a rate of 1°C per minute, and then carbonized in a tube furnace in the presence of pure argon gas for 3 hours. Finally, in order to remove the amorphous carbon, it is treated under pure hydrogen flow at the same temperature for about 1 hour, and then cooled to room temperature under the protection of pure argon.

The WC-supported 20% Pt electrocatalyst was prepared by microwave-assisted ethylene glycol method. Most importantly, put the previously synthesized 0.1 g WC sample into a 100 mL beaker and add 25 mL of ethylene glycol. After stirring for 20 minutes to form a uniform suspension, drop a certain amount of H2PtCl6·6H2O and mix thoroughly. Then slowly add 0.4 mol L-1 KOH solution and mix until the pH value of the solution reaches 10. The mixed solution was ultrasonically shaken for 10 hours. Finally, the mixture was placed in a household microwave oven and heated at 700 W for 1 minute. The sample was washed repeatedly with deionized water and collected by centrifugation.

In conclusion, tungsten carbide hollow microsphere has been prepared with ammonium metatungstate and work as electrocatalyst support for hydrogen evolution reaction. Both bulk WC and Pt supported by synthesized WC are evaluated as hydrogen evolution catalysts. The results show that the synthesis temperature is very important to the composition and surface state of the product, and has a direct effect on the activity of HER. The large WC hollow microspheres show excellent HER activity. 20% Pt/WC also showed better electrocatalytic performance than commercial 20% Pt/C: the current density was significantly increased, and kinetic parameters such as Tafel slope and exchange current density were also significantly improved.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com