Ammonium Paratungstate Utilized in Sulphur Removal of Diesel Fuels

- Details

- Category: Tungsten Information

- Published on Saturday, 05 June 2021 08:51

Sulfur compounds in fuel are converted into SOx when combusted. Furthermore, SOx in automobile exhaust degrades the catalytic converter performance resulting in increased NOx emission which is another important air pollutant. In recent years, ultra-low-sulfur diesel (ULSD) was required in many countries by mandating stringent legislation to cut the S-content down to 10 ppm. At present, the traditional hydrodesulfurization (HDS), a conventional commercial technology, is wildly employed in the purification of fuels. Although HDS can remove various S-compounds such as thiols, sulfides and disulfides, when the deep desulfurization of diesel fuel is required, HDS is less effective due to the low hydrogenation activity to heterocyclic thiophenic compounds

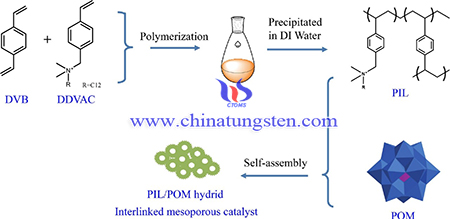

It should be noted that W and Mo-based POMs are the most-used catalysts for oxidation with H2O2 due to their inherent redox properties. The synthesis process of is as below:

4-Vinylbenzyl chloride, N,N-dimethyl dodecylamine, 2,2′-Azobis(2-methylpropionitrile) (AIBN), hydroquinone, acetone, ethanol, methanol, n-dodecane, phosphotungstate acid (H3PW12O40), silicotungstic acid (H4SiW12O40), ammonium heptamolybdate tetrahydrate ((NH4)6Mo7O24·4H2O), ammonium paratungstate(APT) and ammonium metatungstate hydrate ((NH4)6H2W12O40·xH2O) were use without further treatment.

DDVAC was prepared according to the literature with some modification. Simply, 4-Vinylbenzyl chloride (0.2 mol), hydroquinone (0.2 g) and 150 ml ethanol were charged into a flask and vigorously stirred at −20 °C. N,N-dimethyldodecylamine (0.2 mol) which was dissolved in 100 ml ethanol was slowly added into the flask by use of a dropping funnel. The mixture was stirred at −20 °C for 2 h after dropping and further stirred at 25 °C for 48 h. After the reaction, the solvent was removed using rotary evaporation at 30 °C. The obtained solid product was extracted with hot acetone twice, then filtered and dried.

In a typical procedure, 15 mmol DDVAC was charged into a Schlenk flask and dried under vacuum overnight. Then, AIBN (3.5% mol. eq.), certain amount of DVB (1/5, 1/10 or 1/15 mol. eq.), and 15 ml ethanol were charged into the flask. The flask was degassed with five vacuum/nitrogen cycles, and subsequently immersed in a preheated water bath at 65 °C. The polymerization was allowed to proceed under the protection of N2 for 24 h, before the reaction was cooled to room temperature. The polymer was precipitated in pure water, then filtered, washed with water and dried under vacuum at 60 °C for 12 h. The content of chloride ion was determined by the silver nitrate titration method in a methanol-H2O mixed solution with K2CrO4 as an indicator.

The PIL based catalysts were prepared through a direct precipitation method. In short, the polymer (1.5 mmol based on the content of chloride ion) was dissolved into 100 ml methanol, and certain amount of POM was dissolved into 50 ml DI water. The dosages of different POMs are listed in Table S1. The anion exchange reaction was done by slowly dropping the POM aqueous solution into the PIL solution by use of a syringe under magnetic stirring at 60 °C, and further stirred for another 2 h. The mixture was then moved to a hydrothermal reaction vessel and heated at 100 °C for 24 h. The white precipices were then separated, and washed with DI water (50 ml, twice) and methanol (50 ml, twice) successively by centrifugalization. The obtained catalysts were dried under vacuum at 80 °C for 24 h.

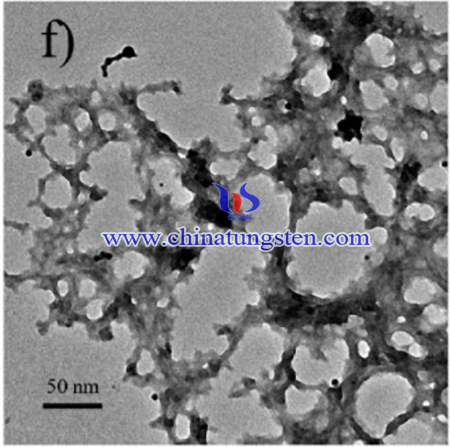

In this work, the simple preparation of novel polymer supported polyoxometallates (POMs) catalysts has been reported. The catalyst with H2W12O4210− as counterion, which exhibited the best activity in the oxidation of benzothiophene (BT) and dibenzothiophene (DBT) to sulfones in model oil with hydrogen peroxide (H2O2, 30 wt%) as oxidant. As for the oxidative desulfurization of a real diesel, the sulfur conversion could reach almost 100%. The catalyst could be reused for at least eight cycles without noticeable changes in both catalytic activity and chemical structure.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com