Bifunctional Catalysts Based on Tungsten Oxide Obtained Using Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 May 2021 22:00

Catalysts based on zircon oxide modified by tungsten oxide have attracted much interest in the last years due their promising application in reactions of great industrial importance, such as n-alkanes isomerization and alkylation process. The catalytic behavior of these catalysts is still not totally comprehended.

Therefore, further research about active sites in this catalyst, their interaction with the support and with the chemical species to be catalyzed is still necessary. Several studies have been accomplished to characterize catalytic systems with the aim to maximize their catalytic properties. Such studies pointed out that the catalytic properties of the WOx–ZrO2 (WZ) system are strongly affected by synthesis method, including every step of the preparation together with the quality of precursors and tungsten loading.

Thus, bifunctional catalysts as Pt/WOx–ZrO2 (PWZ) based on tungsten oxide was prepared using ammonium paratungstate, the catalysts were active in the n-heptane isomerization with high selectivity.The synthesis of PWZ catalysts were obtained by precursor polymeric method as following steps:

Ammonium paratungstate (APT), platinum, zirconyl nitrate, chloride, citric acid and ethylene glycol were used as raw materials without further treatment.

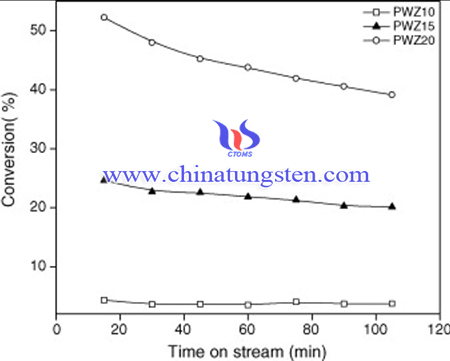

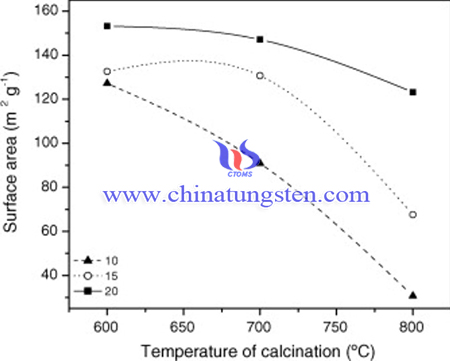

The platinum chloride content was calculated to a platinum loading of ca. 1 wt%. The synthesis procedure to obtain PWZ materials was: (1) stoichiometric amounts of ammonium paratungstate and distilled water were placed into Becker and stirred at 50–60 °C for 30 min; (2) an aqueous solution of citric acid and stoichiometric amounts of zirconyl nitrate were mixed at 60–70 °C for 1 h. The molar ratio between citric acid and zirconia was of 2:1; (3) the solution (1) was added to the solution (2) under constant magnetic stirring and maintained at 70 °C for 30 min; (4) stoichiometric content of platinum chloride solid was then added to the system (3) and stirred at 70 °C for a period less than 10 min; pH 2 was maintained during the reaction; (5) after complete mixing, the temperature was slowly increased to 90 °C, at which point ethylene glycol was added in the mass proportion of 60:40 (citric acid:ethylene glycol). The resulting solution was maintained at this temperature for 1 h under constant magnetic stirring. A gel was then formed and subsequently heat-treated at 300 °C for 2 h. These materials were then calcined at 600, 700 and 800 °C for 1 h resulting in the catalysts which were denominated as PWZ10, PWZ15 and PWZ20 for materials with 10, 15 and 20% of tungsten loadings, respectively. The surface densities of the tungsten were 4 W atom/nm2, 6 W atom/nm2 and 8 W atom/nm2, for the sample with 10, 15 and 20% of tungsten, respectively.

To sum up, bifunctional catalysts as PWZ were prepared successfully through precursor polymeric method. Specific surface area of the PWZ catalysts decreases with the increase of calcination temperature. The PWZ20 sample showed higher conversion than the other samples and its conversion in 15 min of reaction was higher than 52%. The precursor polymeric method here used for synthesis of PWZ catalysts is promising method for production of catalysts with high specific surface area and with activity for the n-heptane isomerization.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com