Preparation Methods of Tungsten Copper

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 May 2021 08:52

There are four main preparation methods of preparing tungsten copper: mixed-press sintering method, activation sintering method, infiltration method, and nano/ultrafine mixed powder sintering method.

The mixed-press sintering method is a traditional powder metallurgy method. First, mix the tungsten powder and copper powder in a certain proportion, and then add the lubricant for mixing. Forming and sintering are carried out after mixing. Sintering generally adopts non-liquid phase sintering. The briquettes are sintered below the melting point of copper. A liquid phase is generated during the sintering process. The other is liquid phase sintering, where the sintering temperature is higher than the melting point of copper. One of the most commonly used is the high temperature liquid phase sintering method. The process is simple, but the sintering temperature is high, the time is long, the performance is poor, and the density is low. At the same time, the wear and tear of the abrasive tools are serious.

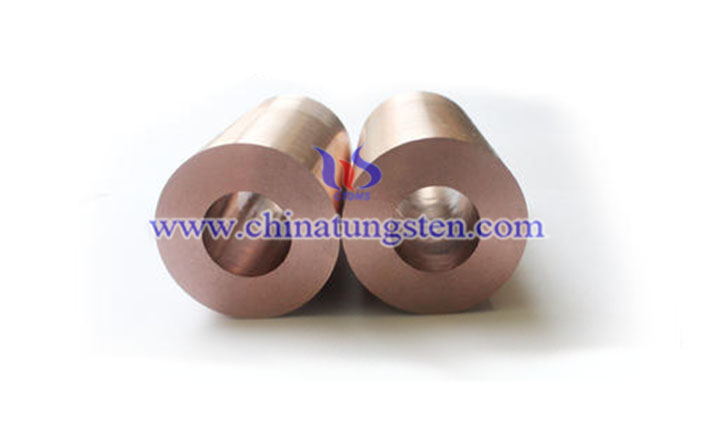

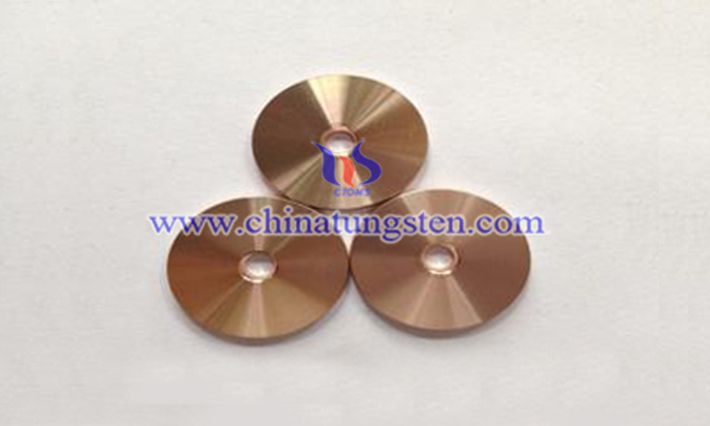

The infiltration method is currently the most used method. First, prepare a porous tungsten framework with a certain density and strength, and then infiltrate copper with a relatively low melting point. This kind of process makes the finished material have uniform composition, high density and excellent comprehensive performance. The tungsten skeleton can be prepared by high-temperature sintering, compression molding, extrusion molding and injection molding.

The activation sintering method is to add trace activation elements in the preparation process of W-CU material to improve the sintering activity. Compared with the high temperature liquid phase sintering method, this process reduces the sintering temperature, shortens the sintering time, and greatly improves the sintering density. Among the activating elements, Co and Fe have the best effect. But the disadvantage is that the activator will reduce the electrical and thermal conductivity of the tungsten copper material.

The nano/ultrafine mixed powder sintering method is a process developed with the development of nanotechnology. The materials produced by this process have very high density, electrical and thermal conductivity. The preparation of powder mainly includes mechanical alloying method, sol-gel method and mechanical-thermochemical synthesis method. The forming process mainly adopts compression molding, injection molding, cold isostatic pressing and hot isostatic pressing.

With the development of the times, there may be a better and more suitable process for industrial production of high-performance W-CU materials in the future.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com